British military leads the world in shooting-range safety

Thanks to Leica Geosystems equipment and the tri-services’ own modelling software

Tens of millions of small-arms rounds, from pistols, rifles and automatic weapons, are fired on Britain’s military training ranges each year. Some of these rounds can travel for kilometres, even after ricocheting. A number of the ranges are small and confined, or have unusual topography. It’s essential, therefore, to protect service personnel and the nearby public from stray rounds and ricochets – but it’s a very complex task.

The MOD owns 240,000 hectares of land in the UK, comprising 16 major and 104 minor training areas, ranges and camps. Over two-thirds of it, known as the defence training estate, is used solely for preparing the armed forces for service. Around 9,000 tri-service personnel (British Army, Royal Navy and RAF) pass through the estate each day.

Safety on the ranges is co-ordinated by the tri-service Defence Ordnance Safety Group (DOSG), led by Major (Ret’d) Charles Ross, previously of the Royal Artillery. He relies on Leica Geosystems equipment, including a UAV (drone), a multi-station and a GNSS rover, to get the job done.

“I can’t commend Leica Geosystems enough for their first-class support. They’ve given us a tremendous amount of advice and are very quick to come out and solve problems for us. We’ve been very lucky that they’re so interested in what we’re doing, and they just never say ‘no’.”

- Charlie Ross, Defence Ordnance Safety Group

Modelling ‘probabilistic solutions’

For each range they’re called in to assess, Charlie Ross and his team need to determine the ‘weapon danger area’. First, they gather industry-standard 3D point-cloud data, using Leica equipment, to map the area. This creates a very precise and detailed 3D digital model of each range, including the relative height and extent of the range floor.

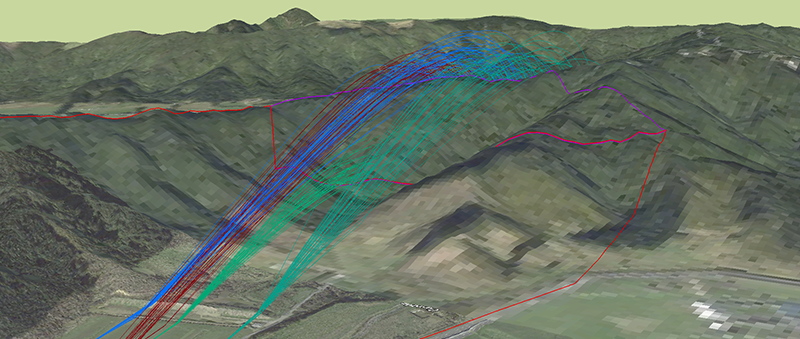

Next, the team feeds the DFX output from those surveys into triangulation software in their world-leading ballistic modelling software, which they developed in-house. This simulates the effect of firing weapons, using highly complex mathematics to model billions of possible trajectories. It identifies where ricochets could occur, and at which angle and distance. This delivers statistical probabilities which, when merged with the topography of each range, determines the weapon danger area.

“No one else in the world does what we do.”

- Charlie Ross, Defence Ordnance Safety Group

Originally developed in 1996, the DOSG’s ‘probabilistic’ model is continually being enhanced to deliver maximum value. That’s why it’s the engine behind models used by other NATO alliance members, including the USA. DOSG also provides global consultancy services in partnership with the International Range Safety Advisory Group; for example, they recently surveyed and modelled two problematic ranges in New Zealand.

From human subjectivity to extraordinary accuracy

According to Charlie: “Before we had the technology, a General would approve a range as ‘safe’ if it had been in use for 100 years and no one had ever been shot there! When it became clear that that was too subjective, smaller ranges and those with more complex topography were simply decommissioned. Then we moved into using an engineering contractor to do our surveys, but it wasn’t very satisfactory.”

Seven years ago, however, DSOG introduced equipment from Leica Geosystems and they haven’t looked back since. Their equipment currently includes:

- The Aibot X6 intelligent aerial surveying UAV (drone)

- The Nova MS60 multi-station – the world’s first self-learning multi-station

- The GS18T – the world's fastest GNSS RTK rover.

Charlie says the Leica Geosystems kit has enabled the team to calculate risks with an exceptionally high degree of confidence. This means they can hold onto even the smallest and most complicated ranges and still keep everyone safe.

“The UAV delivers precision data very quickly. Where once it would have taken several days to photograph and gather point-cloud data for, say, six to eight hectares, we can now do it ourselves in around six hours, from launch to finished product. We know that our results are 99.99% accurate and crucially, we now gather and store all of our data ourselves. With all of the Leica geospatial survey equipment working together, we’ve dramatically improved accuracy - certainty from within five metres to just 10 millimetres today.”

Which is perhaps why the model has never failed in its calculations; failure would mean death or injury to a member of service personnel, an observer or a member of the public. “Our 3D representations are a major step-change in representing, in our model, the ground on our firing ranges, and they’ve never failed us,” says Charlie Ross.