Underneath King’s Cross redevelopment

Case study

Authors: Lidija Špiranec & Steven Thurgood

King’s Cross is one of the most significant reconstruction projects in London, UK. The area around King’s Cross Station had 67 acres of unused land, which was designated for development in 2008. The master plan included 50 buildings, 1,900 new homes, 20 new streets, 26 new public parks and squares and 26 acres of open space.

Renewal work for this major rail hub began in 2010. One of the key constraints of the project was the presence of four railway tunnels beneath the site, which were part of the main connections with King’s Cross Station. These connections are utilised by hundreds of thousands of commuters every day.

For the development project to proceed, it was necessary to build adjacent to and over the top of these tunnels. In conjunction with Network Rail, the asset owner, it was agreed this could take place, provided any movement of the tunnels and track was analysed and a real-time monitoring scheme installed. The monitoring scheme was required to confirm predicted movements, and measure any exceedances, so work could be stopped before any damage to the infrastructure occurred, minimising risks to travellers and trains.

Due to the size of the project, its value and impact, the monitoring system requirements were rigorous:

Robust - to last the contract duration of 12 years

Scalable - to accommodate expansion

Accurate / Precise - to measure and report with confidence

Repeatable - to obtain consistent observation

Automated - to run in an environment with no manned access

Continuous - to operate 24/7

Accessible - to all stakeholders

Pell Frischmann, one of the UK’s leading consulting engineering companies with almost 100 years of experience, accepted this monitoring challenge. Having used various Leica Geosystems’ instruments and equipment for over 30 years, the company knew that Leica Geosystems’ monitoring solutions were the right way to go, on account of reliability, technical excellence, backup and support. Thus, the firm partnered with SCCS Survey Equipment Ltd, part of Hexagon, the UK leading distributor of Leica Geosystems Surveying Equipment, to deliver the required monitoring system.

“Leica Geosystems’ long history of developing new products, whilst fully maintaining backwards compatibility, ensured the system could be expanded with the latest equipment over the extended duration of the project. At the same time Leica Geosystems’ maintenance and support network meant that spare parts and servicing would be available for all purchased equipment, whatever its age, over the entire project life-cycle,” said Gary Weekes, director asset management at Pell Frischmann. “The support of SCCS in helping to specify suitable equipment and assist with setting up the system was also a key driver in selecting Leica Geosystems equipment for the project.”

There were two independent monitoring systems installed at King’s Cross Station – the primary one was geodetic monitoring with automatic total stations (ATS) and the backup one was geotechnical monitoring, providing redundancy in measurements, delivering additional information and increasing certainty and reliability of results.

Tailored solution for London’s tunnels

The equipment used for the project consisted of following sensors:

|

Thameslink Tunnels: |

Gasworks Tunnels: |

|---|---|

|

|

The Leica TM30/50 monitoring total stations provided the ability to narrow the measuring laser beam detector sensitivity, eliminating the risk of interference from adjacent targets in these long linear sites, which is a unique ability of Leica Geosystems’ instrumentation. This enabled the system to be configured with fewer total stations while still maintaining the target frequency required by Network Rail. The monitoring instrumentation automatically measures:

-

3D tunnel displacement by measuring five prism arrays attached to the tunnel lining at 10m cross sections

-

Rail geometry for cant, twist, gauge and alignment by measuring prism pairs attached to each rail of the track

Outside of the tunnels, a permanent network of stable control points was measured to eliminate the movements of the total stations.

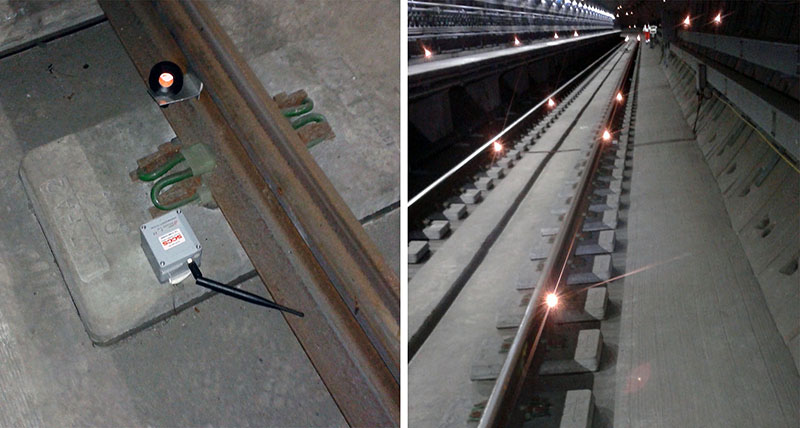

The wireless tilt nodes were installed on the tunnel lining adjacent to the crown prism and track bed/sleepers at 3m intervals to mirror rail prisms. The wireless tilt and distance nodes were located on the tunnel lining at each 10-m cross section to measure convergence and ovalisation of the tunnel.

Once everything was installed, a track geometry measuring device with scanner and its dedicated software was used to measure/verify the tunnels and ensure the monitoring equipment was clear of passing trains and kinematic envelope.

Data acquisition and processing of all geodetic and geotechnical measurements were facilitated using Leica Geosystems GeoMoS Monitor. The software allowed for assigning priorities and control of observations, whereas the frequency of observations was remotely adjustable to match dynamic events. The computed results of prism measurements were further used for computation of virtual observation points for mathematically derived values, enabling complex calculations from a variety of data sources into a single computation model. Deformation movement limits, alarms and actions were defined with bespoke variables depending on activity and instrumentation. Data visualisation and reporting were seamlessly integrated using the cloud-based service from Leica Geosystems GeoMoS Now!.

Due to the complex environment and long linear nature of the project with only stable areas at each end, the total station data required correction to a homogeneous model rather than each unit working independently. Thus, a fully-integrated and automated least square adjustment of the control network was computed real time during the observation cycles using Star*Net software by MicroSurvey Software Inc., part of Hexagon. The GeoMoS system was then automatically updated with live network adjustment coordinates for the entire network prior to each monitoring array observation.

“The use of GeoMoS Now! enabled us to establish simple, clear dashboards for the project. At any time, there were multiple contractors onsite, who were only interested in individual sections of the monitoring scheme. GeoMoS Monitor allowed specific alert regimes to be established for each contractor, with individual dashboards developed in GeoMoS Now!, which were login specific to that contractor.“, explained Weekes.

Overcoming monitoring challenges

There were several complex challenges that the Pell Frischmann team had to overcome during the monitoring period. In the Thameslink Tunnels, trains were passing at 50 mph every five minutes, causing vibration and air movement, affecting instrument orientation and level. The access to the tunnels was limited to two four-hour shifts every three months, so a permanent solution was found by installing GeoLaser AD-12 self-levelling tribrach to enable remote users to correct the total station back to the horizontal plane without requiring access. This was fully controlled via GeoMoS Monitor.

In the Gasworks Tunnels there was a different challenge to be overcome – an oily soot residue. The brickwork in the tunnels had thick layers of it built up over time from the years of steam and diesel trains operating in the tunnels. This caused constant residue built up throughout the monitoring period. Therefore, the total station optics and prisms needed to be cleaned every couple of months to maintain signal strength, as part of the active maintenance plan.

Over the life of the installation, the monitoring scheme operator with continued support from SCCS found innovative solutions to increase system reliability and reduce operational costs. This also included anti-corrosive fittings and prism covers which made them resistant to constant exposure to previously unknown environmental conditions discovered in the tunnel.

“The equipment delivered accurate and repeatable results 24/7 for extended periods of time without the need for manual intervention between the standard bi-monthly maintenance visits. This was particularly important in the Gasworks tunnels, where diesel residue and water leakage caused a particularly harsh working environment, in which the instrumentation had to operate faultlessly for 12 months between servicing,” said Weekes.

The reliability and accuracy of the equipment ensured that all work on the development near the tunnels could continue without any delays a decade later from 2010. This instilled confidence in the system from Network Rail and there has been no need to stop or slow trains, avoiding any financial penalties delays would have incurred.”

Future-proof monitoring data

Once the regeneration of King’s Cross is completed, monitoring of the tunnels will continue. The importance of this dataset rests in recording the natural movement and condition of the tunnel. This could become an important asset for engineers to determine life cycle extensions of the tunnels and to plan preventative maintenance.

“The client and all stakeholders were very happy with the system and its performance. They particularly liked the real time unlimited access to the data, which enabled them to check any minor triggers and see trending without the need for any specialist knowledge or training on the system. We plan on sharing our level of satisfaction with this product within this collaborative network of companies, so it can be utilised on a wide range of projects,” concluded Weekes.

“Pell Frischmann provides innovative solutions working closely with Leica Geosystems and wider Hexagon team. They have responded promptly to any issues, including out of hours and have saved the project from the costs of any delays to trains”, added Alastair Mitchell, project director of Kings Cross Partnership.