Mitigating Risk with Integrated Data from Two Mine Monitoring Technologies

Protecting the safety of mine workers, communities and the environment whilst maintaining efficiency relies on continuous monitoring of the pit slopes for surface movement, instant analysis of the data, and a fast response to deformation alerts. Responsible mining companies depend on advanced monitoring technologies to generate accurate, real-time information on structural behaviour to prevent a disaster.

Risk management strategies in Brazil’s mining sector have been written into law in recent years after two devastating structural failures at tailings dams resulted in extensive loss of life, widespread destruction and environmental contamination.

Brazil ranks among the top three producers of iron ore globally and is a leading exporter of the high quality grade required for steel production. Minas Gerais state, in the southeast of the country has some of the largest reserves, with deposits routinely extracted from open pit mines.

Among the many Brazilian mines adopting Hexagon’s monitoring solutions is JMN Mining. Working to the highest standards of operational safety, JMN Mining and Ferro+ Mineração, part of the J Mendes Group, extract, process, and commercialise between 7 and 9 million tonnes of iron ore annually from Congonhas-Outo Preto and Picacema-Desterro de Entre Rios mines.

The company runs two mines in Minas Gerais, both deploying Hexagon’s integrated monitoring systems with total station and radar to measure and check for instability 24/7, with processing, analysis and reporting of the data in real-time.

At Congonhas-Outo Preto, the smaller of the two pits, JMN Mining deploys complementary monitoring sensors and software from the Leica Geosystems and IDS GeoRadar portfolio for instant detection of surface changes.

A Leica TM50 I imaging total station provides automated, high accuracy 3D measurement to prisms, and HYDRA-X, a portable radar system verifies and tracks displacements. The compact Hydra-X is ideally suited to the tactical monitoring of critical areas at this site.

The total station data is acquired by Leica GeoMoS Monitor for instant processing and analysis. The results are integrated within IDS GeoRadar Guardian software, with immediate notifications available to the geotechnical team. By integrating monitoring information from both sensors, JMN has a holistic, continuous view of the structure. The safety and security of workers and quality assurance of the operation is protected since risk management is based on comprehensive, accurate, real-time data.

Optimising and Expanding Monitoring Capacity

With successful implementation of continuous, integrated monitoring at one site, JMN sought advice from Hexagon Mine Monitoring experts on expanding capacity to the larger Picacema-Desterro de Entre Rios mine, where distance from the radar to the mine surface varies between 450m and 1.4km.

To detect new areas of movement and monitor previously identified areas, JMN needed a combination of total station and radar for continuous, high accuracy measurement over long range with 360° coverage. Working with Rafael Cruz, Senior Commercial Technical Consultant at Hexagon, JMN installed new hardware, comprising of a Leica TM50 I monitoring total station and an IBIS-ArcSAR Lite radar system with integrated GNSS for georeferencing, including specific features to overcome the challenges of a tough mining work site.

The rugged and reliable TM50 I, with long-range automatic target recognition (ATR) up to 3000m is an ideal total station for the precise 3D monitoring of prisms around the mine. In addition, the IBIS-ArcSAR Lite radar configuration gives an all-round field of view, high spatial resolution, long-range (2500m), a 360-degree scan time in less than 4 minutes and a complete data set for immediate analysis. With low power consumption and solar panels, continuous scanning through all-weather conditions is made possible with the advanced atmospheric correction algorithm, ensuring data integrity is maintained and identification of slope movement verified.

Seamless synchronisation of total station data from Leica GeoMoS and radar data from IDS Guardian was achieved through the HxGN GeoMonitoring Hub, a single software platform that combines, analyses, visualises and cross checks all measurement results delivered by automated monitoring systems.

After an initial period of training with the hardware and software, JMN additionally contracted 24/7 Monitoring services, establishing a two-month project to fully evaluate the safety and efficiency benefits of continuous data monitoring and integration through the GeoMonitoring Hub software.

For the duration of the project, Raiana Ribeiro, Vitor Brito and Rogério Weigert, Hexagon’s dedicated team based in Brazil, provided 24/7 remote monitoring services for analysis, interpretation of radar data, plus reports and notifications on displacement for effective and timely support to JMN’s geotechnical team

Márcio Philip, Coordinator Geotechnical Engineer at Ferro+ Mineração commented, “Hexagon’s industry-leading monitoring products, from manufacturers synonymous with accuracy, quality and innovation, are trusted and reliable. This reputation and our previous experience with them guided our decision to expand our use of Hexagon’s monitoring technologies and support services.”

Conclusive Monitoring Results Enhance Safety

A complete and continuous understanding of surface movement is critical for the early detection of slope instability hazards and accident prevention. This proved to be the case when a visual inspection identified an area of surface instability on the slope, prompting further investigations using radar and total station measurements to prisms for fully informed decision-making.

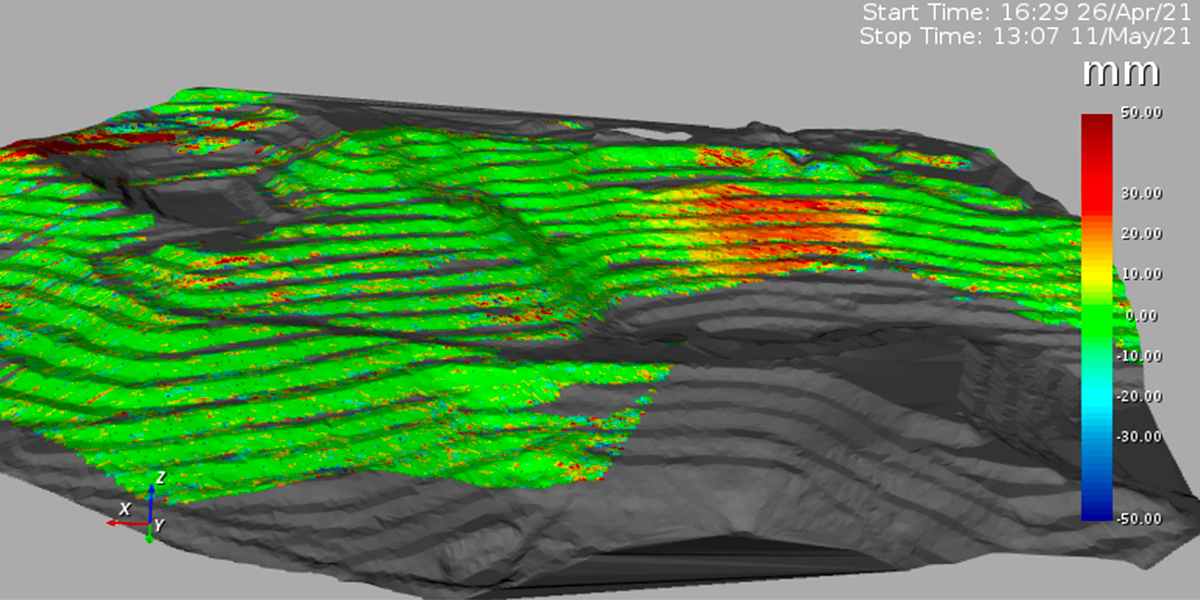

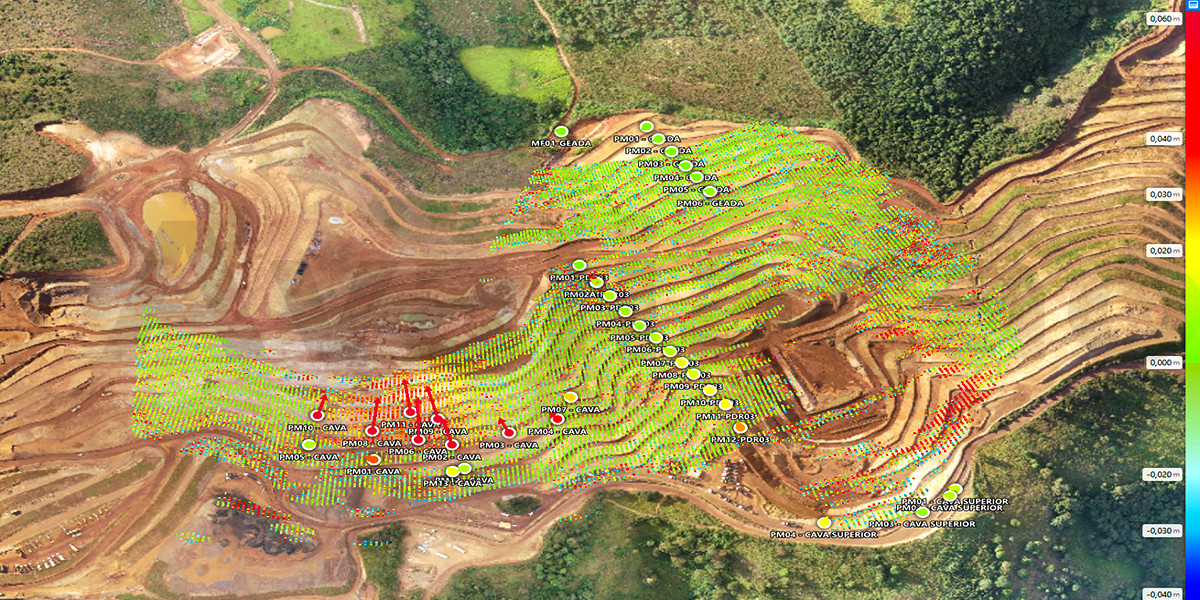

IBiS-ArcSAR and TM50 I data was analysed with GeoMonitoring Hub software to cross check and validate that areas of movement captured by the radar were the same as those where movement of prisms had occurred. By monitoring these displacements, with real-time notifications of surface deformation, it was possible for the field team to plan and carry out early-stage containment repair work and alert those responsible for operational safety to take appropriate action. Data analysis continued after the repair work to confirm stability.

Integrated, state-of-the-art monitoring technology and 24/7 remote monitoring services effectively prevented an accident, protected the safety of workers and the environment and avoided the costly and damaging impact of downtime.

Márcio Philip commented, “Without a doubt, the biggest benefit of continuous integrated monitoring resides in identifying displacements in the structure and using the data to minimise risks and impacts in the mine operation. Through monitoring we had a precise map of this area of deformation and the information that we needed to not only plan repair works, but to follow up after they were completed to guarantee operational safety. With the reliability of data generated by two systems at the same time, the quality of the sensors, (as both showed the same result), plus the capacity of the GeoMonitoring Hub software and the external backup of the 24/7 Monitoring room, Hexagon has shown us that its technologies and services work together in an integrated way and this is very beneficial to us all.”

Future Development through Automated Monitoring

As a result of the evaluation project JMN Mining has made further investments to increase the deployment of automated monitoring technologies. In the coming months data from the IBIS-ArcSAR, Leica TM50 I, Leica TM60 and Leica MS60 with laser scanning capability, will all be managed through Hexagon’s 24/7 monitoring services, providing a comprehensive suite of advanced solutions to obtain the maximum from the collected data.

Accurate, comprehensive integrated data from complimentary monitoring technologies, together with a robust reporting system, supports effective decision-making, empowering geotechnical teams to carry out early-stage remedial work and prevent accidents.