Customer Insight: Doubling Speed and Increasing Accuracy with the Leica AP20

Testing the AP20 proves benefits across survey work for expert surveyor and CEO in France

France’s ATGTSM specialises in surveying and geomatics services including topographic and cadastral surveys, 3D laser scanning, underground infrastructure detection and mapping, drone surveys, and more. With locations across France, they serve a range of clients from government entities to companies and private individuals. To accomplish this breadth of work, their surveyors and specialists utilise high accuracy instruments and advanced software, providing data-rich deliverables to clients.

ATGTSM uses a range of Leica Geosystems instruments in their surveying workflows, including the Leica TS16 and Leica TS60 robotic total stations, Leica GS18T GNSS smart antenna, and Leica RTC360 3D laser scanner. When the Leica AP20 AutoPole was released, they wanted to see if it lived up to the hype and would make a good addition to their toolkit, arranging to test the AP20 for a week.

The CEO of ATGTSM and expert surveyor, Arnaud Colin, shares his experience testing the AP20 in some of the company’s most common surveying workflows, including outcomes that culminated in the decision to purchase AP20s for several locations.

Quickly reaching and recording difficult points

The AP20 addresses one of the major pain points in robotic total station measurement workflows by eliminating the need to level the pole. Instead, ATGTSM technicians can record points with a tilted pole, providing access to more points and speeding up the overall data capture process.

“When you have a normal pole, you have to level it vertically, which means that if there are overhangs or other obstructions between the instrument and the pole, you can’t see the prism. You must either make offsets using topographical calculations, or record distances manually and shift the pole. It’s quite complicated,” explains Colin.

“With the AP20, you can tilt the pole and the point is captured exactly at the right place. The busier the environment, the more this happens. Working on a busy road, you have a lot of points where you would need to shift or measure off-centre, and this is where the AP20 is most relevant.”

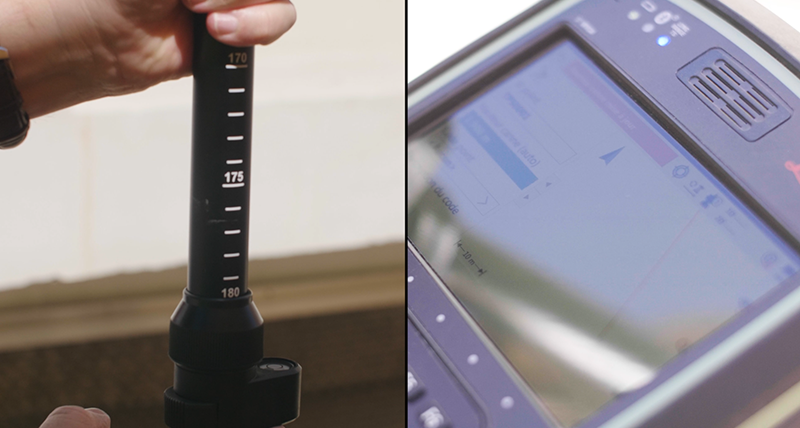

Certainty and flexibility with automatic pole height

PoleHeight is another one of the AP20’s accuracy enhancing functionalities that automatically updates pole height changes in the field software. With no need to read, check, and enter height changes, surveyors have greater flexibility to alter pole heights as the situation requires while maintaining certainty that correct heights are captured. This makes the survey work in the field faster and, by digitalising the process, eliminates pole height corrections in the office.

“With automatic pole height, the main gain is the accuracy and therefore the reliability of the plans in the end,” says Colin. “It also frees the technician’s mind from having to think about this all day in the field and he can change the pole height a little more often, with a little more confidence.”

Time saving TargetID

TargetID is another feature of the AP20 that brought benefits to the ATGTSM workflow, enabling the total station to search, identify, and stay locked onto the AP20’s prism alone – particularly helpful on busy sites with multiple prisms in operation or other reflective surfaces.

“The main benefit for using the TargetID is time savings because it happens quite regularly that the total station aims at a mirror or something reflective that is not the prism,” says Colin. “Thanks to TargetID, this problem is eliminated.”

Overall results: easy integration, faster measuring

“The results of the test of the AP20 are largely positive,” concludes Colin. “The technicians have integrated the AP20 into their work processes quite easily.”

And the biggest benefit for Colin and the ATGTSM team? Time savings.

“I estimate that the time saved by the AP20 is about 30 to 50% depending on the type of site,” he says. “The more complicated the site is, the more barriers and elements that disturb the line of sight between the device and the pole, the more time we save.”

Significant time savings translated into trust and investment for Colin, who decided to purchase AP20s for the ATGTSM surveyors at two locations, with plans to expand use across the company.

“We already decided to buy two AP20s for our offices in Vitrolles and Aix en Provence, and we think that in the near future all the offices will be equipped with AP20s.”