Innovating as-built verification

Case study

Author: Yoshie Katagiri

In 2018, the Japanese Ministry of Land, Infrastructure and Transport (MLIT) publicly invited bids for a ‘Project to Introduce and Utilise Innovative Technology to Dramatically Improve Productivity on Construction Sites’ under its i-Construction initiative aiming to boost productivity on construction sites as part of a wider innovation strategy. Kanatsu Giken formed a consortium of four companies with Fukui Computer Co., Ltd., Leica Geosystems Co., Ltd., and Sanyo Sokki Co., Ltd., and tendered for the project. The consortium was selected in the category of ‘Techniques Using Data to Improve the Productivity of Construction in Civil Engineering Work.’

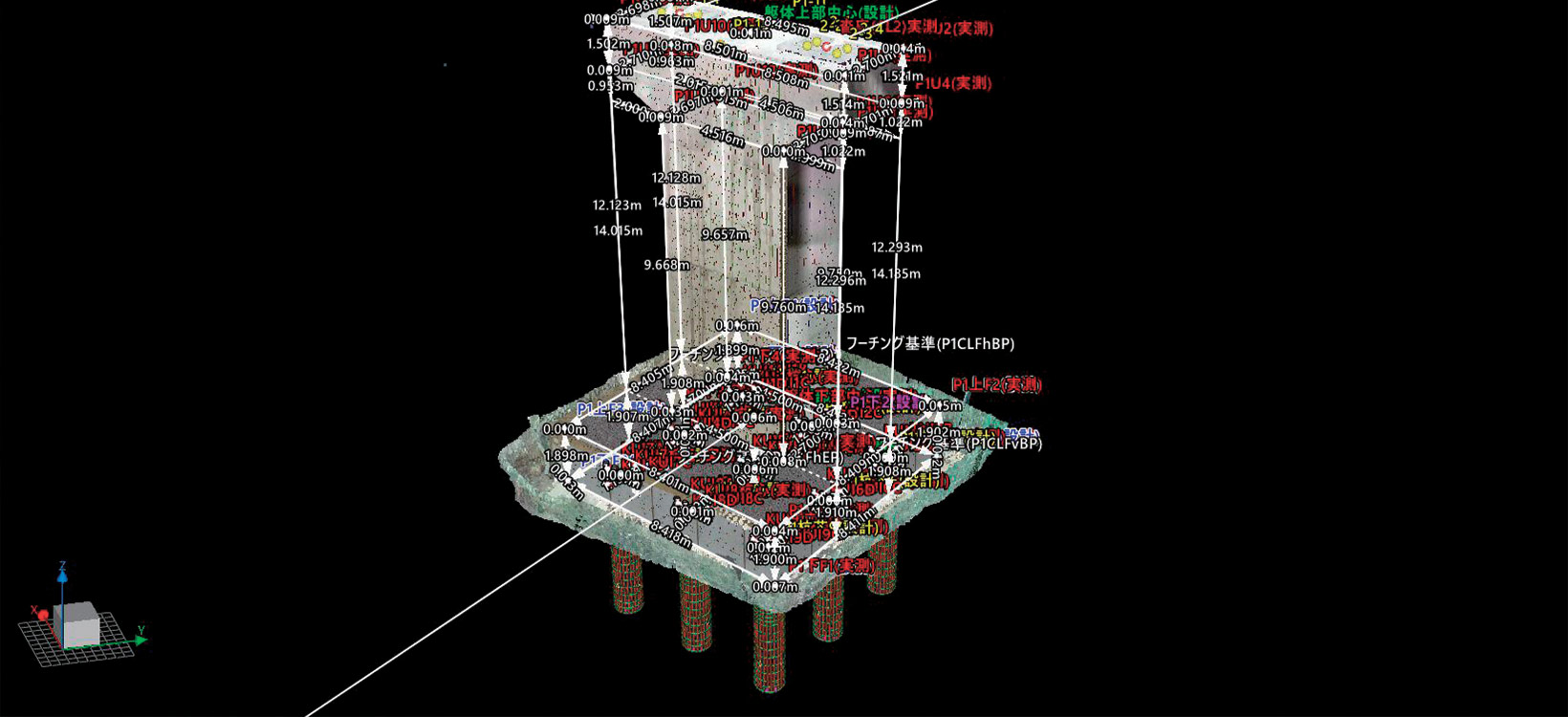

The objective of the four-company consortium was to conduct 3D laser scanning on concrete structures, such as bridge abutments and piers, and use the acquired point cloud data for as-built verification to dramatically improve the productivity of construction sites. In addition, they trialled and proposed a new method of progress management using the differences between the captured point cloud data and the coordinate values of the 3D design data (CIM).

Kanatsu Giken used Leica Geosystems’ Leica Nova MS60 MultiStation, an instrument capable of 3D laser scanning with the surveying functions of a conventional total station.

“Current as-built verification method is time-consuming and labour intensive because much of the measurement and analysis of disparities is done manually. The reason we bought the Nova MS60 in the first place, was to make these tasks less labour intensive. Soon after the purchase, we found out about the MLIT project. We focused the expertise available across the four companies and came up with a specific method for construction management using points and surfaces. This also had the potential to enable high productivity when verifying the as-built, so we tendered for the project,” describes Yoshinobu Kimura, team leader of the information technology group in the civil engineering division at Kanatsu Giken.

The consortium conducted field measurements and data analysis at five sites and based on the results, compiled and submitted recommendations to MLIT. In 2019, MLIT announced their evaluations of all submitted projects – this consortium won an ‘A’ rating, the highest evaluation.

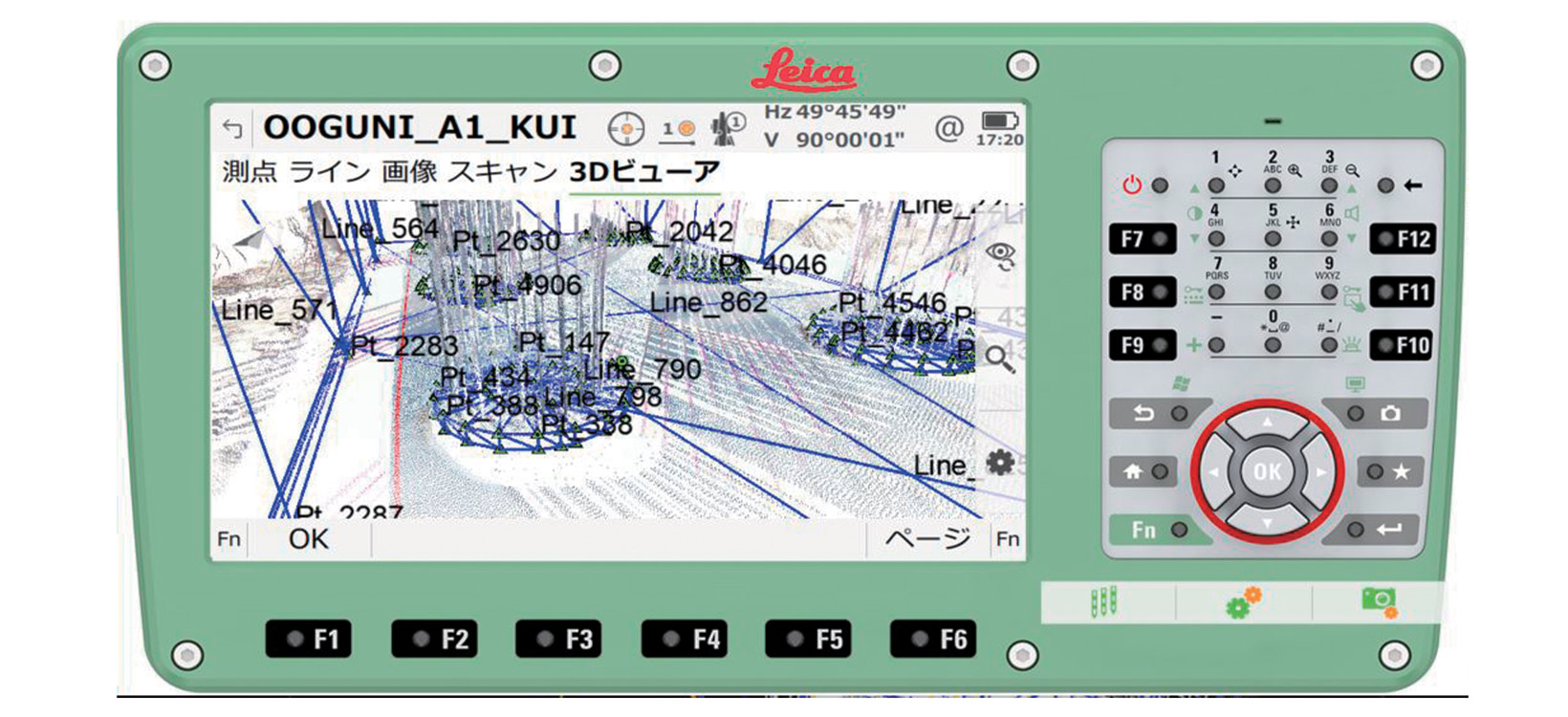

Comparison between point cloud data obtained by measuring the as-built of cast-in-place piles and 3D design data (blue lines)

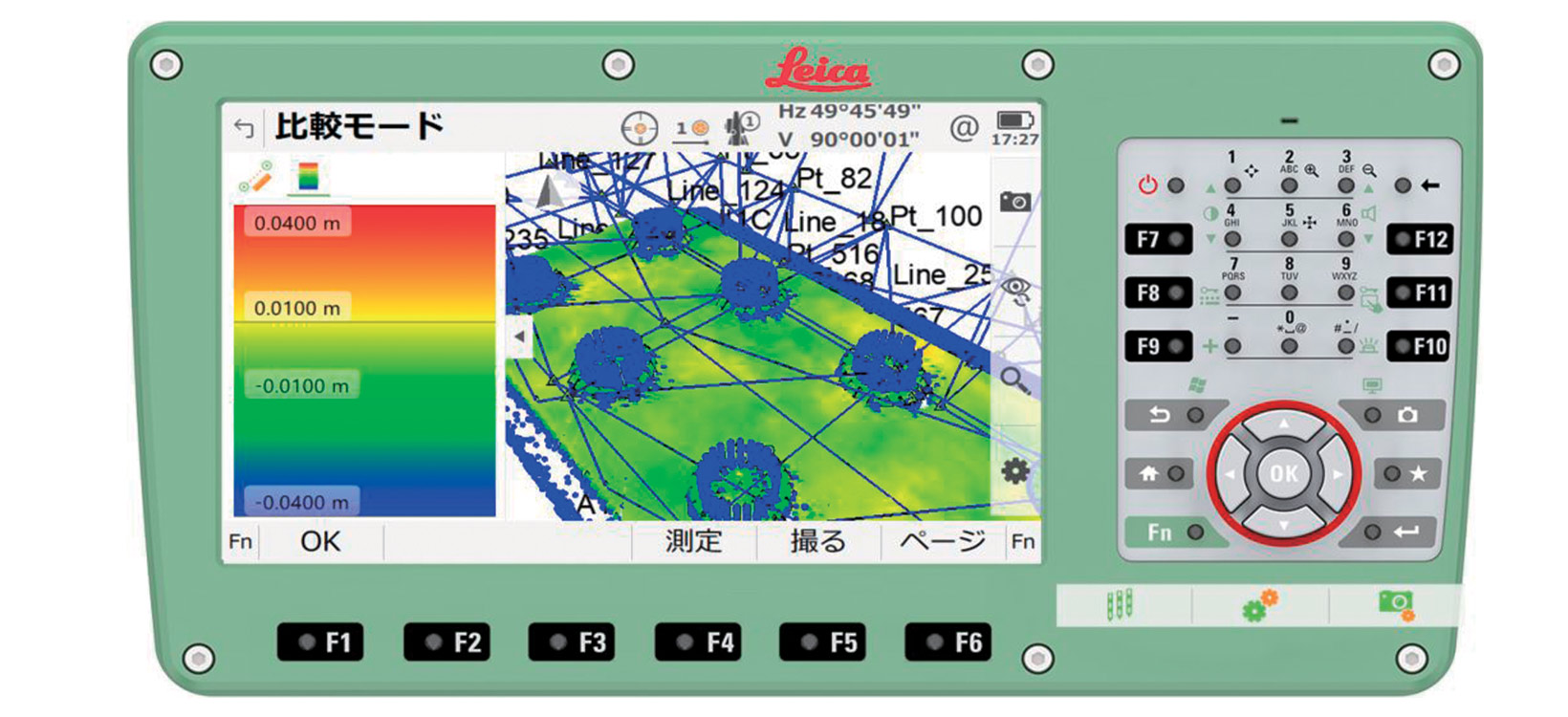

Planar (roughness) comparative evaluation of point cloud data obtained by measuring the as-built of cast-in-place piles against 3D design data

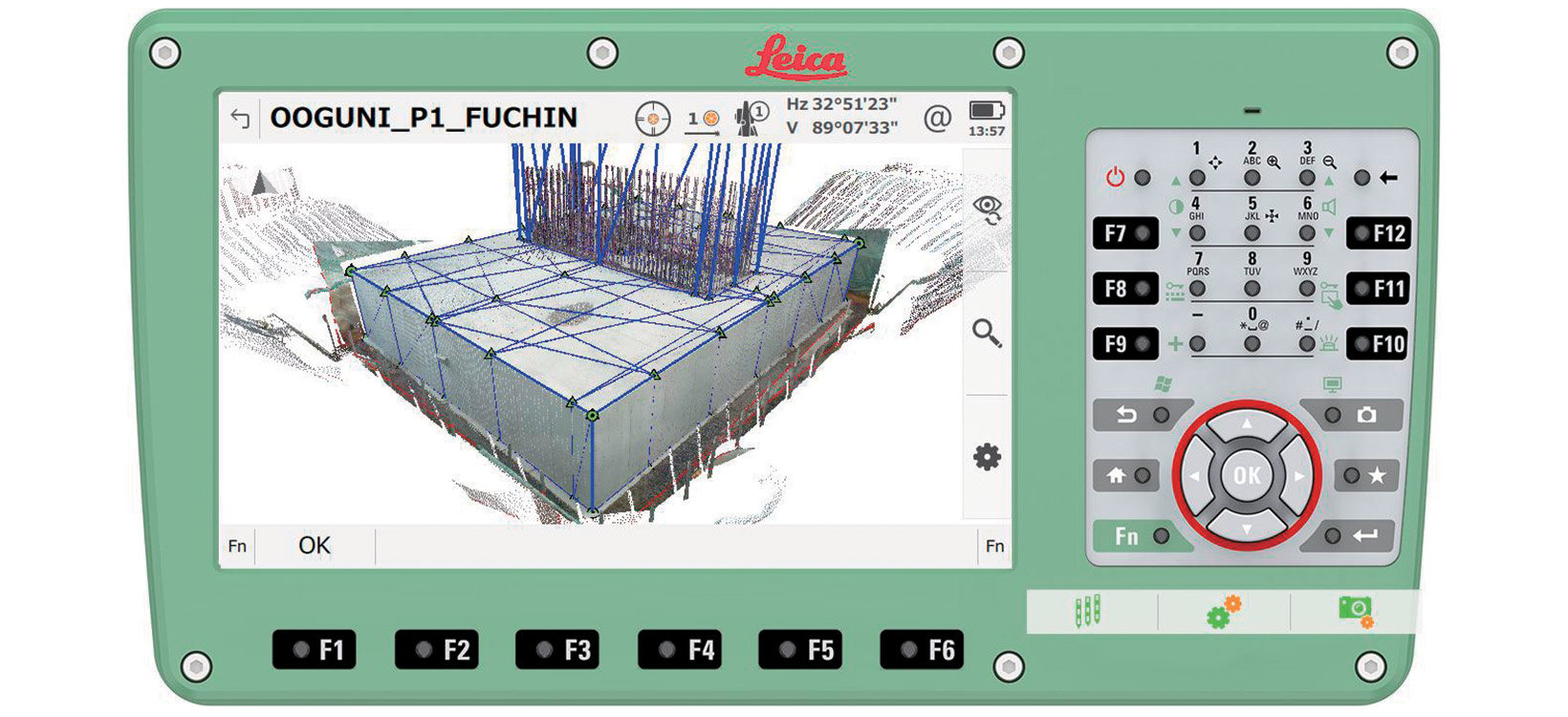

Comparison between point cloud data obtained by measuring the as-built of footing and design data (blue lines)

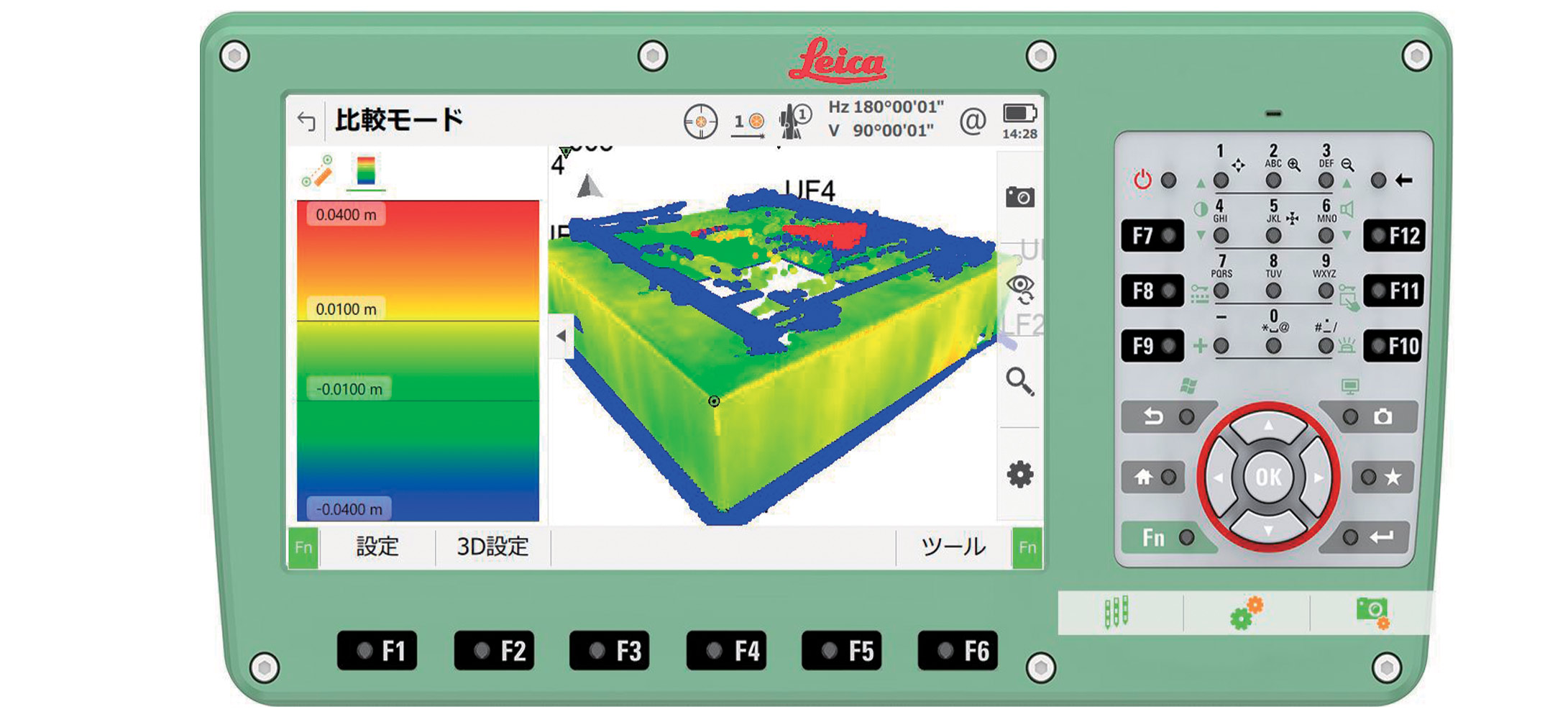

Planar (roughness) comparative evaluation of point cloud data obtained by measuring the as-built of a footing against the 3D design data

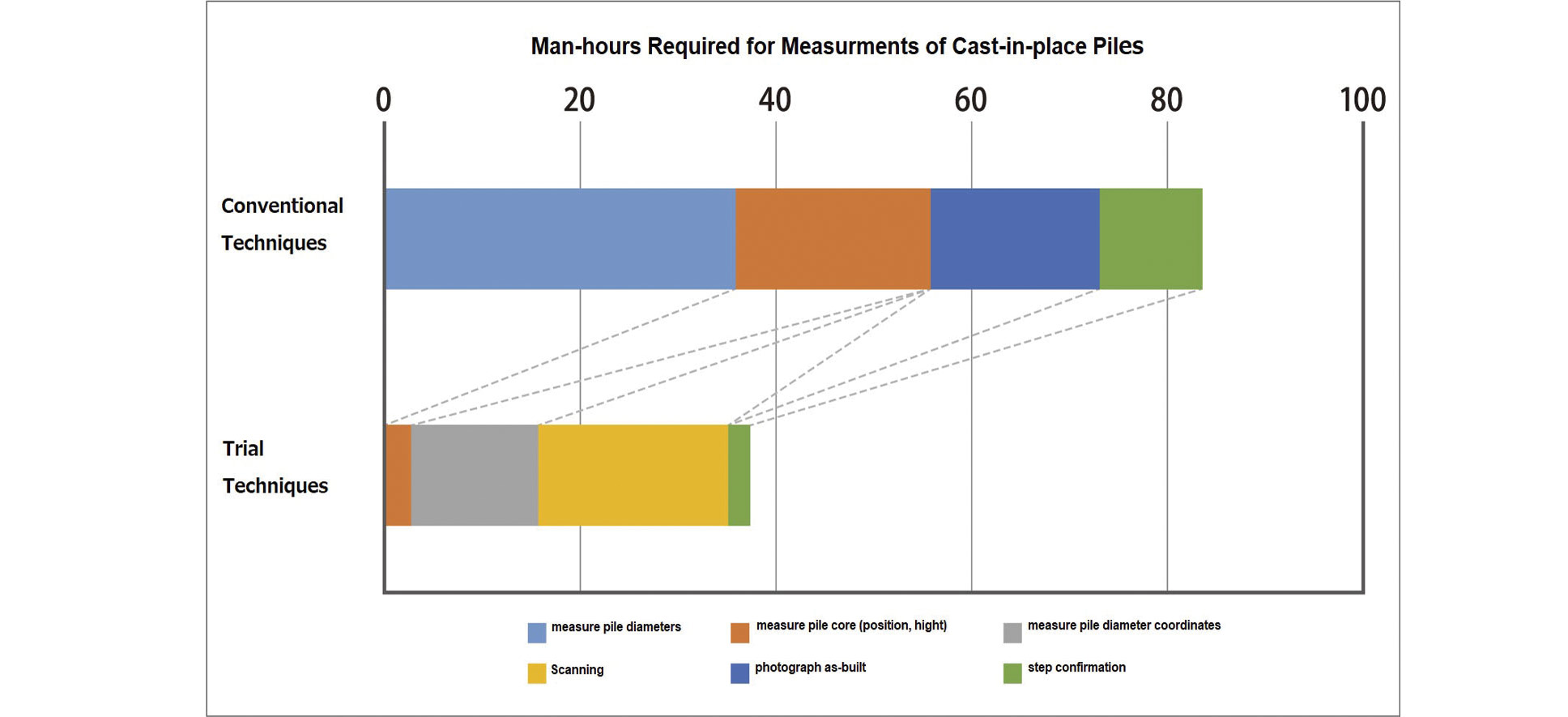

By conventional techniques, it takes a total of three people - a pair taking measurements and a photographer - to measure the as-built of the cast-in-place pile.

With the trial techniques, one person can operate the Nova MS60 to perform measurement and photography. The trial techniques reduced the number of man-hours required for measurements of cast-in-place piles by more than half.

The footing is a reinforced concrete foundation with shock-absorbing function. As it is chamfered, reading of accurate corner points can be an issue.

Manhours for measurement work halved

In the case of piers, due to the requirement to take measurements at height and in confined spaces, planar evaluations using 3D point cloud data is very useful.

The trial was run for the as-built measurement and verification during the construction works on two bridge abutments and two bridge piers of the outer and lower portions of the Ohguni Viaduct in Japan. The results from the trial were divided into cast-in-place piles, footings, and housings.

To be able to efficiently conduct accurate as-built verification of the entire top of the pile was one of the great advantages of the trial technology.

“With the conventional method, when we measured the standard height of the top of the pile, we used a stepladder or something similar to climb over the reinforcements that protrude from the pile and had a surveyor stand in the centre. The pile diameters were measured by teams of two, taking measurements in two directions - one along the axis of the bridge, and the other, perpendicular to this. This work was repeated again and again until all the piles were measured. Another worker was needed to take photos of the as-built verification process.

With the Nova MS60, you can measure from outside the steel reinforcements. It’s no longer necessary for surveyors to work in pairs to measure the pile cores and pile diameters with tape measures and then calculate the central points, as these can be accurately determined later by data analysis,” explains Kimura.

The MultiStation reduced the manhours required for the measurement work to less than half. Worker downtime got reduced from 83.3 manhours with the conventional techniques to 37.27 hours.

In addition, because the data captured by the Nova MS60 is uploaded to the point cloud processing system for the as-built measurements, there is no need to take photos for as-built verification separately. This also eliminated the time involved in organising the photos after the work on site.

The footing is a foundation of reinforced concrete placed on top of the cast-in-place piles. In the trial, the scaffolding proved to be an obstacle. The piers sit on the footing and support the bridging superstructure.

For the piers and footing, scaffolding proved to be an obstacle and the instruments had to be moved frequently. In spite of this, the trial task took 8.5 manhours compared with the 11 manhours for the footing and 30.9 manhours compared with the 40 manhours taken with conventional techniques.

Comparison of point cloud data obtained by measuring the finished shape of the pier and the design data (blue line)

Planar (roughness) comparative evaluation of point cloud data obtained by measuring the as-built of a pier against the 3D design data

“For footings and piers, we only managed a manhour reduction of around 20 per cent. But in cases where there are many structures to measure, even 20 per cent represents a substantial saving. Also, if 3D laser scanning is established as a standard process, construction sites will devise workflows for building and removing scaffolding so that measurements can be performed efficiently, and this should reduce manhours even further,” says Kimura.

Use of point cloud data boosts productivity increases accuracy and improves safety

This innovative method of as-built verification using point cloud data has a myriad of potential benefits, including higher productivity, higher accuracy, and improved safety. Furthermore:

• As-built measurement can be performed by a single worker.

• Once the data has been captured, it is possible to measure dimensions between arbitrary coordinates or view cross sections at any position.

• It is no longer necessary to take and organise as-built verification photos.

• Being able to calculate XYZ axes deviations is unprecedented and has the potential to increase the precision for maintenance and management.

Even after the construction has progressed and the piles and footings are buried underground and invisible, the status of these invisible structures can be accurately gauged and carefully managed in the future. Keeping a detailed record of the construction process improves safety and reliability and can be expected to reduce the incidence of major accidents.

Moreover, the opportunities for application are likely to expand. Potential uses include uploading the captured data to CIM for processing and combining of the above techniques with VR (virtual reality), AR (augmented reality) and MR (mixed reality) technology, and wearable terminals, changing the nature of construction work.

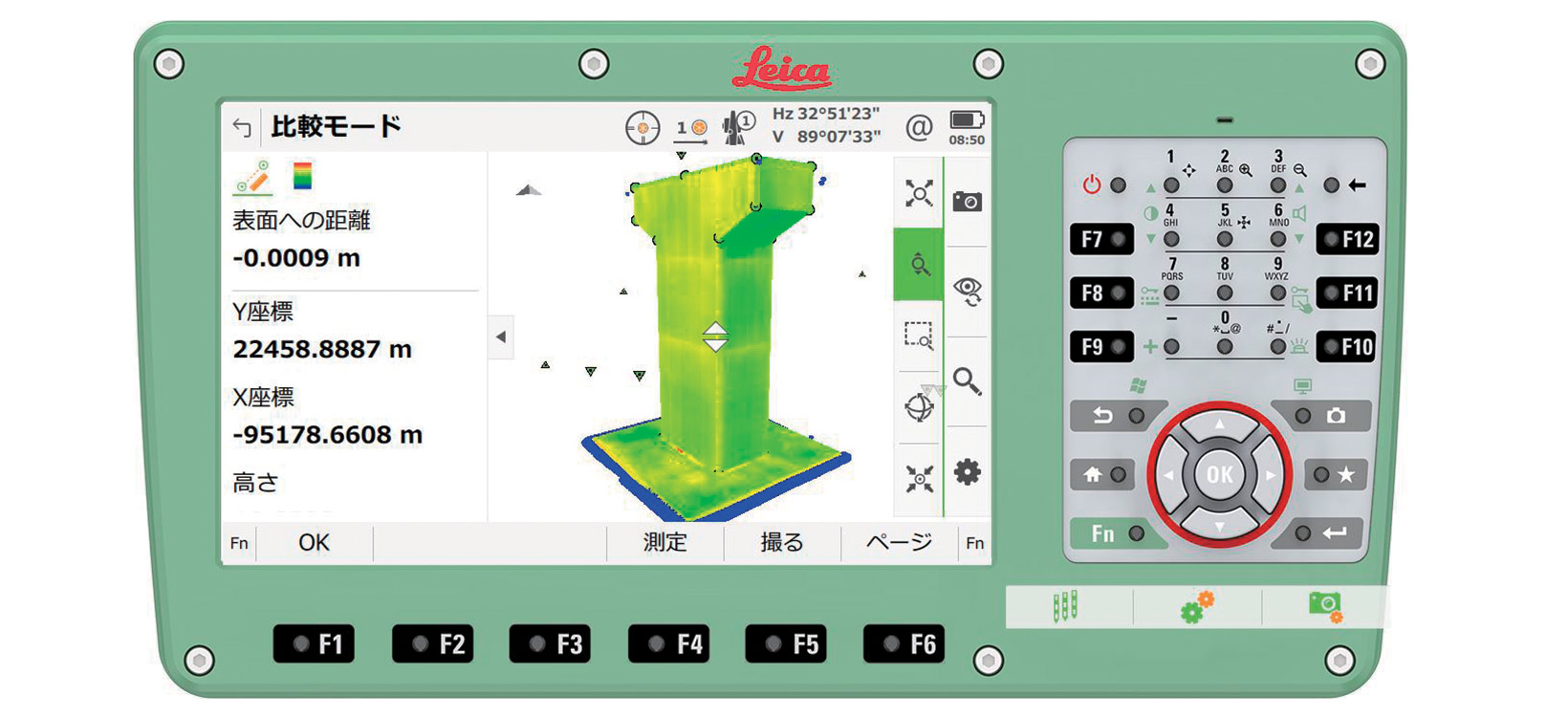

Immediately view 3D design data superimposed on point cloud data

Merged as-built point cloud data of the entire structure with 3D design data (CIM).

The ease of use, a familiar operating interface of a total station combined with a high-performance motor drive for high-speed rotation and inversion, and a high laser scanning speed resulted in complete user satisfaction.

“The greatest benefit of the Nova MS60 is that you can view 3D design data superimposed on point cloud data in real time – you simply look at the screen on the Nova MS60 on-site and see the differences immediately. If a reading is not within the standard value range, either the measurement position or something else is wrong. And so, by checking against the 3D design data as you work, you can verify the as-built without mistakes,” explains Kimura.

Kanatsu Giken conducted this trial project with the theme to ‘Make the most of technology in the field’ and brought together engineers and the construction site in pursuit of innovation.

“In this trial, we simply put a proposal into practice, showing that there is an alternative way to do things. As the requirements change due to the shift from engagement to full adoption of i-Construction, we will continue to embrace flexible thinking and creativity to improve productivity on construction sites and make the sites a more attractive place to work,” concludes Kimura.