Digitalising from planning to execution

Customer profile

Author: Reka Vasszi

As the Internet of Things (IoT) continues to become more universally available, technology is transforming the way entire industries conduct business. With leading-edge technology, previously manual-based processes have become more automated and that enhanced visibility increases productivity and efficiency both on the job site and in the office.

Brandsma Digitaal Meten, a land surveying company in the Netherlands, provides innovative and smart solutions across different fields, including:

- Building construction

- Surveying

- Civil engineering

- Infrastructure analysis

- Yacht construction

Developing innovative, quality and tailored solutions for each customer is a priority for Brandsma Digitaal Meten. To achieve this goal, the company uses the most advanced technology for its projects, and its portfolio includes various Leica Geosystems products, such as:

- Leica ScanStation P40 terrestrial laser scanner

- Leica RTC360 3D reality capture solution

- Leica BLK360 imaging scanner

- Leica Geosystems smart antennas

- Leica Geosystems software solutions:

- Leica Infinity survey software

- Leica Cyclone 3D point cloud processing software

- Leica Cyclone REGISTER 360 3D laser scanning point cloud registration software

- Leica Exchange data transferring solution

- Leica ConX cloud solution and web interface

- Leica Captivate surveying field software

- Leica iCON construction software series

“At Brandsma Digitaal Meten we look forward to every new challenge and we always go for quality. That is why we work with the latest equipment and software available on the market,” said Rein Brandsma, founder and owner of Brandsma Digitaal Meten. “Our latest addition to our equipment portfolio is the new Leica RTC360 3D laser scanner, which is an efficient product in coping with the multitude of challenges and environments we are facing.”

Taking the lead from planning to execution

The right dimensions serve as the basis for every building project, whether it concerns the construction of a house, a factory or a bridge. Specialists at Brandsma Digitaal Meten are involved in every stage of a project from initial planning to execution and monitoring.

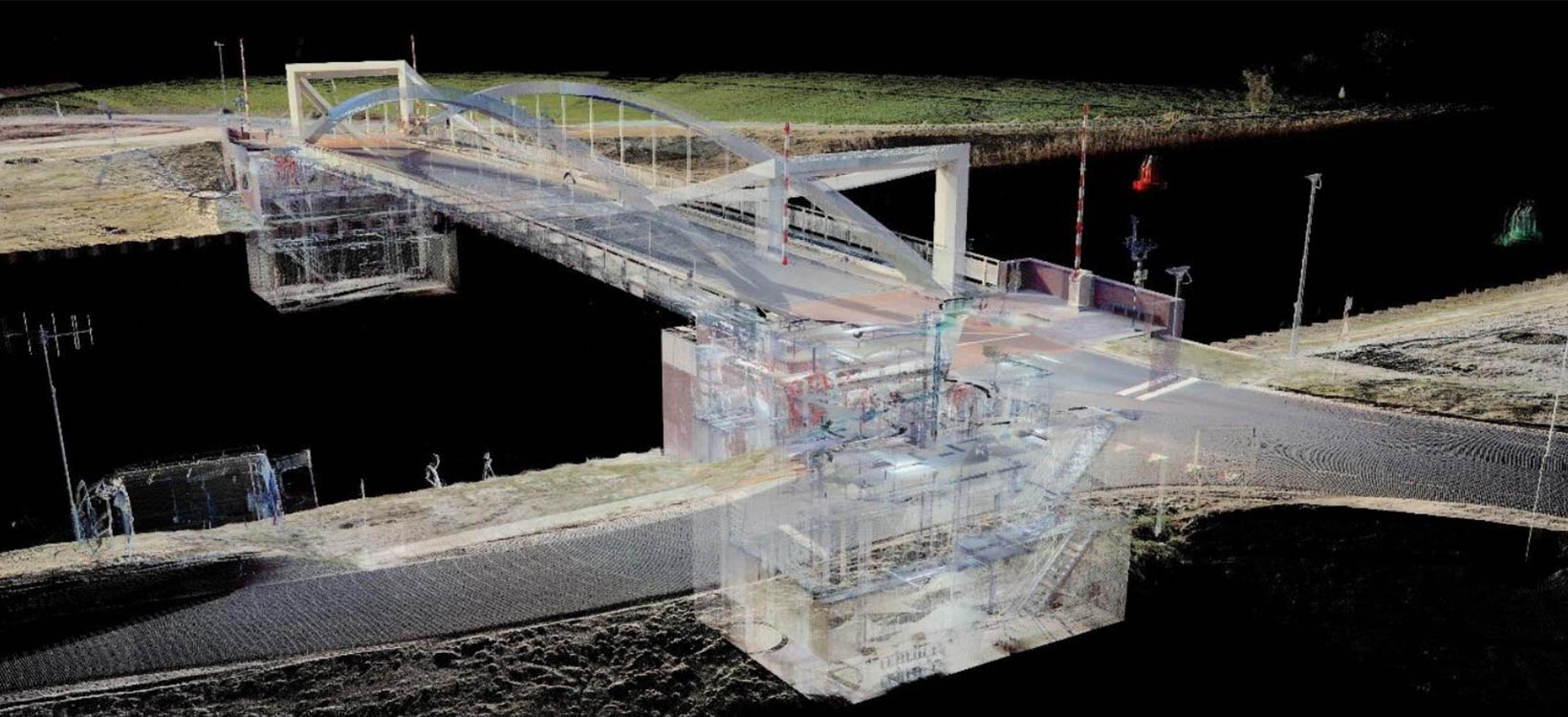

The company has gained extensive experience in scanning bridges and developing 3D models and 2D drawings. In their latest project, Brandsma Digitaal Meten scanned a new bridge in Aduard, the Netherlands, to perform a dimensional check of the retrieval mechanism. Once the bridge was scanned with the Leica ScanStation P40 terrestrial laser scanner and the data registered in Cyclone REGISTER 360, 3D models were created through Autodesk Recap™ and Autodesk Revit™.

Digitalising factories

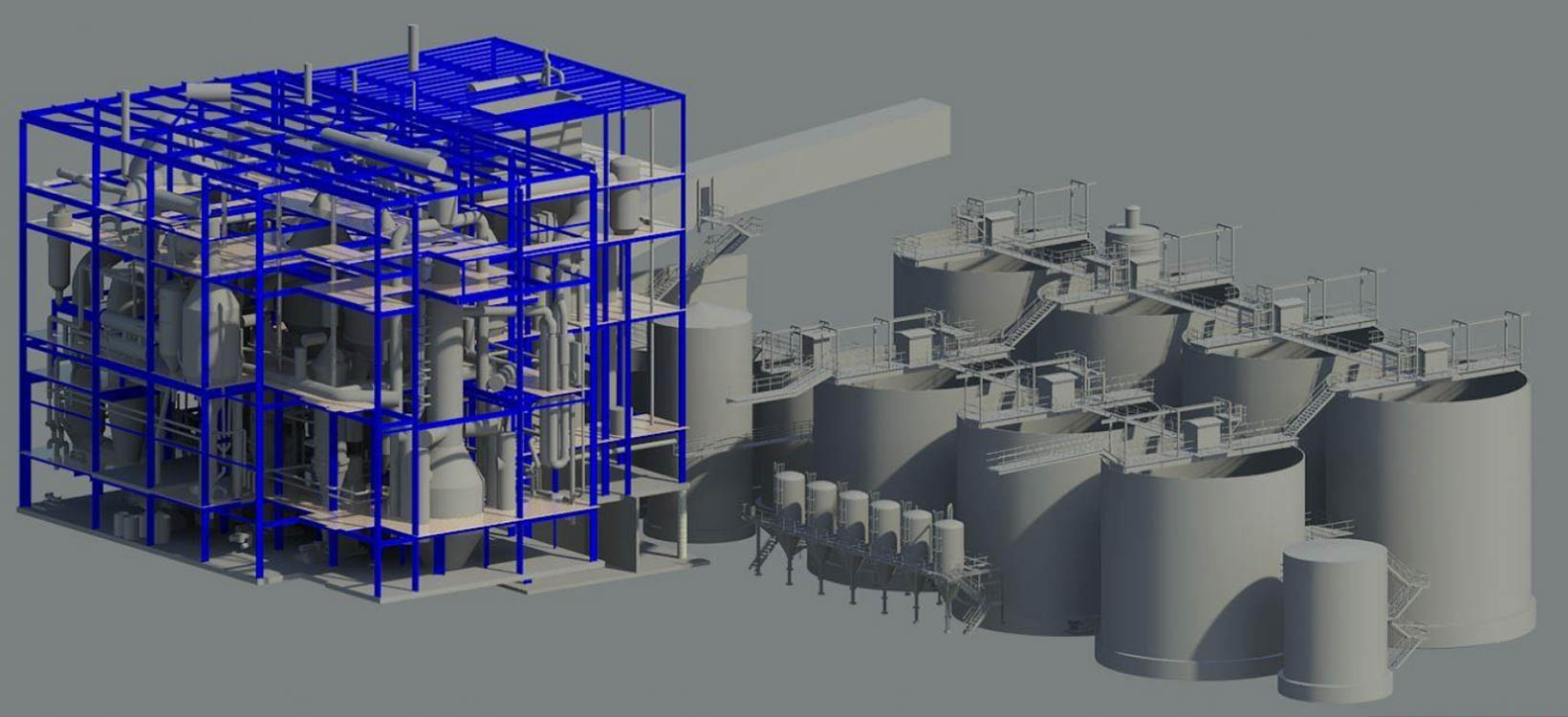

Re-modelling a complete factory or developing production lines require detailed measurements and drawings of every part of the facility so the modifications can be effectively adjusted. Accurately measuring the whole building could be time-consuming, so Brandsma Digitaal Meten experts offer complete 3D laser scanning from machine components to factory halls.

One of the leading salt producers in Europe, the Salinen Austria AG, asked Brandsma Digitaal Meten to scan their entire factory and produce a 3D model of the infrastructure. With the help of the detailed and accurate 3D model, Salinen Austria AG can now modernise the salt factory and lead the 7,000-year-old tradition of salt mining in the Salzkammergut into the future.

Visualising ships in 3D

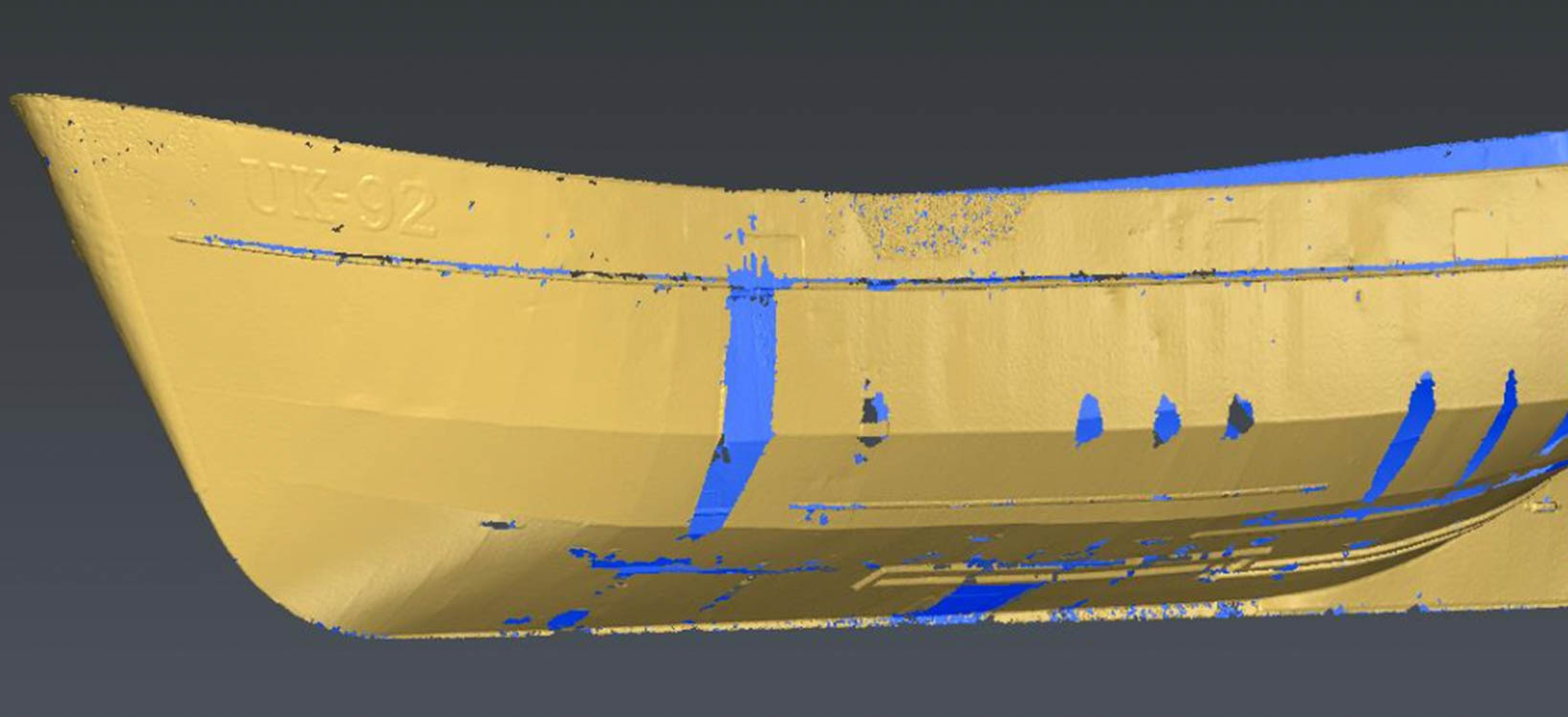

Brandsma Digitaal Meten is also engaged with the yacht- and boat-surveying industry and measures entire ships or different parts of a vessel. Visualising the ships in 3D enables the effective maintenance of yachts and serves as a basis for further development or replacements.

The UK-92 fishing vessel was built in 1983 and is in need of a renovation. Before maintenance could be carried out on the ship, the customer asked Brandsma Digitaal Meten experts to scan the entire vessel and identify the parts of the hull that needed to be replaced. Once the ship was scanned, the raw data was registered in Cyclone REGISTER 360 and a refined mesh was created with 3DReshaper point cloud processing software. The mesh provided was imported by Brandsma Digitaal Meten’s client into a 3D modelling software to calculate the water displacement and stability of the UK-92 fishing ship. The data acquired also helped the customer to re-build and replace parts of the fuselage.

Developing smart solutions

Digitising construction, building or surveying projects, from initial plans through execution can significantly increase productivity and efficiency. Brandsma Digitaal Meten's smart solutions cover the full life cycle of a project. The company leverages Leica Geosystems' state-of-the-art technology to always offer the best solution for each and every customer.