Building a fast track between Germany and Denmark

Case study

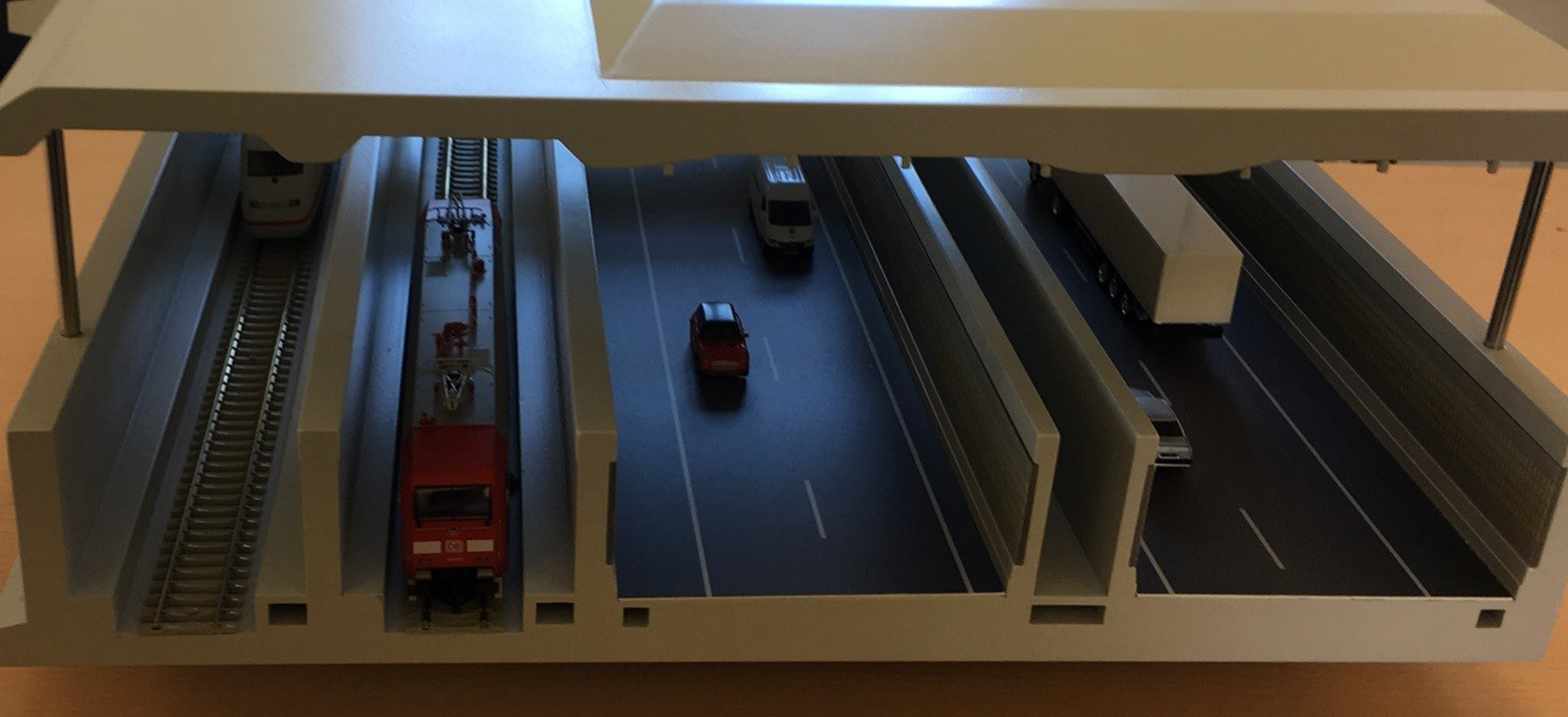

The Fehmarn Belt Fixed Link is a planned immersed tunnel proposed to connect Germany and Denmark, allowing travellers to go by train between countries in only seven to 10 minutes or drive through a four-lane motorway. Upon completion, this 18-kilometre-long tunnel will be the world’s largest tunnel of its kind and is expected to employ up to 3,000 people. The Fehmarn Belt Fixed Link is a user-financed 7 billion Euro project, expected to be completed in nearly nine years, that would connect Puttgarten on the German island of Fehmarn and Rødby on the Danish island of Lolland. Along with the Øresund fixed link between Copenhagen and Malmö, the Fehmarn Belt Fixed Link will bring Scandinavia and Central Europe closer through the named North-South corridor.

Preparing for the tunnel

Preparatory construction work for this European mega project.

Holbøll A/S, a Danish construction company carrying out quality work in the fields of soil, concrete, sewerage and coating for both private and public builders, plays an important role on this project with the earthworks for 56 bridges on the Ringsted-Rødby line, the main route crossing Denmark leading where the tunnel would start. Holbøll’s undertakings for this European mega project includes drainage work for the new bridges as well as building the ramps to the bridges. With a total of three years, expected to be finished soon, this is the biggest project the company has ever undertaken.

The company’s success is based on adapting to the new challenges and changes that the market constantly creates. This approach enabled the company to win the sub contract to support the railway network works between Ringsted and Rødby. With approximately 130 employees and a machine park of 22 machines equipped with machine control from Leica Geosystems, Holbøll's delivers innovative and sustainable solutions on time and at the agreed price.

At one of the bridges in Vordingborg, operator Flemming Ove Nielsen uses Leica iCON GD4 3D system on the 61PX Komatsu dozer to do the first rough work for building the slopes.

“The dozer is very efficient for this sort of work because it can move so much dirt and, with machine control, hold the correct angle of the blade,” explains Carl-Ole Holbøll, co-owner and managing director of Holbøll. “Flemming uses machine control for creating the slope and then the excavator takes over for the final grading work,” says Holbøll.

The dual GNSS solution for dozer is an advantage because the slope is so steep, and to achieve an accurate cross-slope, dual GNSS is required.

Further down the rail track by 5 kilometres, another bridge ramp is under construction. The excavator uses Leica iCON iXE3 3D system for the finishing layer of the ramp slope. The operator has used the solution to document the height of the different dirt layers by simply placing the bucket and letting iXE3 register the height for the as-built documentation and payment release. This saves a lot of time because the operator doesn’t have to wait for a surveyor to do the as-built documentation for each layer.

Building a greener corridor

Along with the tunnel, the upgrade and expansion of the rail link between Ringsted and Lübeck will deliver a shorter and faster connection. The Fehmarn Belt Fixed Link is part of the European TEN-T network whose objective is to enhance the efficiency of the infrastructure and reduce the environmental impact. The objective of TEN-T is to transfer more freight from roads to rail, reduce energy consumption and ease road congestion. The infrastructure for rail freight will be significantly improved because freight between Scandinavia and the rest of Europe would no longer need to drive across Storebælt in Denmark, and the rail freight will be shortened by 10 km.

Paving the next steps

Using a dozer for the heavy-duty earthworks.

The responsible company, Femern A/S, has taken the next steps developing the area where the factory for the tunnel elements will be built. Continued archaeological surveys, preparatory supply infrastructure and drainage has been financed at 55 millio Euros. Geared with Leica Geosystems, Holbøll A/S has prequalified for several of the derived projects, including the draining and moving of eight hectares in Strandholm Lake in Denmark.

Reporter subscription

Contact Leica Geosystems

Want to learn more? We're here to answer your questions.

Want to learn more? We're here to answer your questions.