Adding Real Customer Value with the Leica MS50 MultiStation

By Angus W. Stocking

WestLAND Group, Inc., a firm based in California with expertise in engineering, surveying, GIS, mapping and more, spent years looking for the right 3D laser scanner. While they knew the potential of adding scanning to various projects, there wasn’t yet a huge demand from clients and buying a dedicated scanner seemed like too much of an investment.

With an already efficient topographic and as-built survey workflow, WestLAND wanted scanning to fit into and extend their processes. Therefore, they began to look with special interest at instruments that combined scanning and total station capabilities. The addition of a scanner, however, would only make sense if it could provide the speed, point density, and precision they needed as part of a high-definition solution.

Ultimately, WestLAND chose the Leica MS50 MultiStation in 2013 – a complete robotic, reflectorless total station that could be put straight to work on WestLAND’s typical topo, boundary, and construction surveys. The MS50 also created opportunities to integrate scanning into design and as-built surveys – a great way to market scanning and expand their services into scanning-specific projects.

Soon, WestLAND was incorporating scanning into many services, including rail, building façade, and pipeline as-built surveys. Just as they hoped, adding scanning was a relatively easy extension of their effective workflows, including processing and creating deliverables with point cloud data.

The following three projects describe and demonstrate the breadth of WestLAND’s expanded service capabilities with the MS50 and the benefits for their business.

Improved deliverables for as-built surveys: housing redevelopment project

When an existing client asked for an as-built survey of an office building to support redevelopment as a condominium in southern California, WestLAND saw an opportunity to demonstrate value-added deliverables with the MS50.

They provided a survey of the building interior and submitted a condominium plan. Additionally, they surveyed the exterior to support façade renovations and redesigns for compliance with the American with Disabilities Act of 1990.

As they were going to be there anyway, they decided to scan the façades as well. While the client and wasn’t paying for scanning, WestLAND knew they could perform the scans quickly and it would be a good way to show their new service potential.

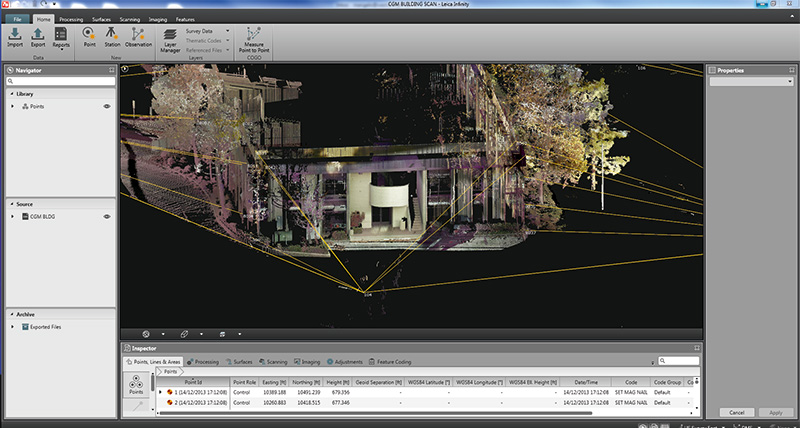

After processing the point cloud in Leica Infinity surveying office software and importing it into Revit and AutoCAD Civil 3D, WestLAND Survey/GIS Analyst Matt Corcoran modelled and rendered the building exterior and surrounding topography, which meant they could provide a deliverable to the project architect created in the familiar Revit environment. This provides a useful starting point from which design firms can further build out a BIM model.

The client was able to use the point cloud data for design and presentation purposes and was delighted with the extra value. With the MS60, WestLAND was able to provide a much better deliverable with a small extra time investment.

Control and scanning for the “Impossible Railroad”

A month after WestLAND received the MS50 MultiStation, clients J.L Patterson & Associates (JLP) from a rail specialised engineering company requested ground control for a mobile LiDAR survey. Already sophisticated users of 3D geospatial data, JLP wanted WestLAND to set control along and within several railroad tunnels near the Mexican border, with someone else doing the LiDAR work.

WestLAND suggested they not only provide control, but also scan one tunnel to demonstrate the deliverable and determine if it was cost-effective. The offer was accepted and WestLAND got to work.

The delivery was ultimately for the Pacific Imperial Railroad (PIR) on a section known as the “Impossible Railroad” – so called for the complex engineering logistics of the early 20th century build that included bridges over large gorges and 17 tunnels. PIR is rehabilitating the Impossible Railroad for use with double stacked trains, and all tunnels will have to be surveyed for clearance analysis and possible grading and track redesign.

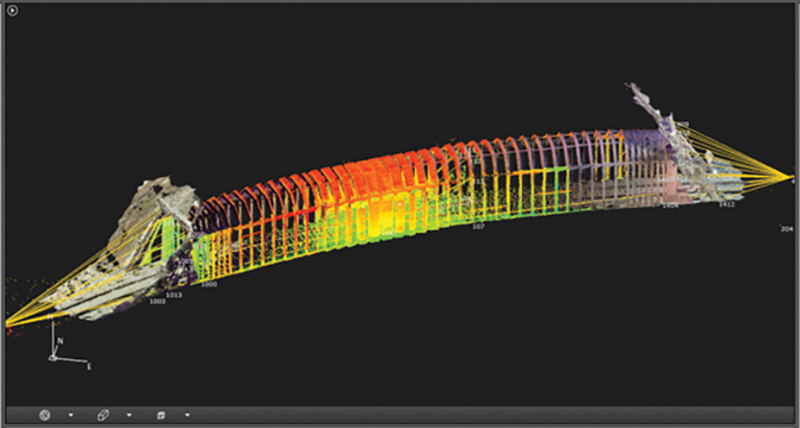

WestLAND saw a scanning demonstration as a marketing investment and offered to scan a smaller, 300-foot-long tunnel. While traversing the tunnel with the MS50 for the control survey, the equipment was switched to scan mode and, after a few setups, they immediately started scanning. The entire tunnel only took a few more hours to scan while giving the engineers time to clean up notes and sketches and take picture of the site to supplement the MS50’s images.

They processed the collected data with Leica Infinity, an invaluable software tool for WestLAND’s engineers to import and view the raw survey and scan data together. They also used Infinity to easily make control traverse network adjustments for precision using conventional survey points and point cloud data. The data was then exported into multiple file formats and imported directly into MicroStation, AutoCAD Civil 3D, and Revit, depending on the application and required deliverables.

The data collected from this pilot project was successfully received and has turned into a further proposal to the client for the remaining 16 tunnels.

Bridge clearance survey – adding scanning to a familiar workflow

Another project started with JLP requesting WestLAND to perform a clearance survey of an existing bridge, along with surrounding topography along existing track in a railyard. WestLAND had done similar projects for JPL, but this time, thanks to the good outcome of the rail tunnel project, scanning was included in the specifications.

The fieldwork was straight-forward: they had to set up on both sides of the bridge for control and conventional topo, so the addition of scanning only took about an hour. This time, they performed a total of four scans, five to fifteen minutes apiece depending on density, from already established setups. They also took reflectorless shots on key features to compare these to the point cloud for quality assurance purposes, and everything was within millimetre accuracy.

After that, the entire project, including point cloud, control, and topography, went straight into Leica Infinity for adjustments and then into JLP’s preferred CAD environment for line of work, breaklines, and contours. It only took about an hour to review an incorporate the point cloud into the drawing and was a good example of a pilot project paying off with new work.

Delivering on promises: cost-effective service expansion

A surveyor at WestLAND summarises their experience with the MS50 and says it lives up to the claims:

“After a few hours of training from the dealer, we were able to get to work immediately on actual projects and provide high quality 3D deliverables with minimal extra time. Processing all the points together in one environment is a real time saver. We’re looking forward to using it more and are already under contract to provide an as-built of a pipeline network located in a steam power plant. That work that would have been very difficult for us to perform cost-effectively without a good scanner.”

Ultimately, with the MS50 WestLAND was able to seamlessly integrate scanning into their familiar workflows and deliver cost-effective value to their customers through 3D model deliverables.