Digitising the construction site from the air

Feature

Author: Anne Pitkaenen

The construction industry hasn’t traditionally been considered as the most agile one in adopting new technologies and jumping into digitalisation. However, when it is of importance to the industry – getting a clear understanding of the project’s progression, a matter of cost savings or safety – changes do happen fast. This can be seen for instance in the wide adoption of machine control systems due to the automatisation, traceability and accuracy they bring into any project.

Large construction sites are like huge living organisms - they need a constant flow of current information to run smoothly. Unmanned Aerial Vehicles (UAVs) fit well to feed current data to create a clear view on site progression, adding safety and increasing cost savings.

Many analysts claim that construction is one of the biggest areas of growth in commercial UAV and at Hexagon's Geosystems division we see it happening. A couple of years ago some companies said the orthophotos and 3D models created for construction projects were opened maybe once and then left unused. Access to fresh data, nowadays, starts to be an expectation by construction professionals. UAVs have been called the 'democratisation tool' for geospatial data since they offer fast access to information, are becoming easier to operate, and the operating cost is a fraction of other data collection methods.

The Leica Aibot CX UAV solution for construction is Hexagon's Geosystems’ answer to the current and future UAV needs of any construction site. This UAV solution opens opportunities for daily progress documentation, stockpile monitoring, resource tracking, and 2D and 3D site survey to get cost savings and visibility over suppliers. Aibot CX brings the construction site into the digital age and turns data into intelligent information to improve decision-making processes.

UAVs can assist construction companies in various ways, from marketing pictures to 3D survey data and from progress reporting to site safety analysis. The following three use cases present common ways how UAVs maximise efficiency, add transparency and offer immediate savings for any construction project.

Surveying the construction site

Through the entire construction project, accurate and up-to-date 3D data and orthophotos of the area are crucial for planning and design. For planning and designing, users need proper as-is information. The more complete the data set, the more efficient the plan will be. UAVs can provide recent and frequently updated data whenever it is needed.

Depending on the construction site, there are several data collection methods already in place, such as:

- Machine control

- GPS

- Total stations

- Laser scanning

- Rotating lasers.

UAVs will not and should not replace these solutions but can complete the view and put additional points in the right place. It is important for the UAV workflow to fit into the existing workflows and solutions. UAVs are an excellent solution for accessing hard-to-access areas, widening the view by covering the surroundings and combining aerial data with data collected from other systems.

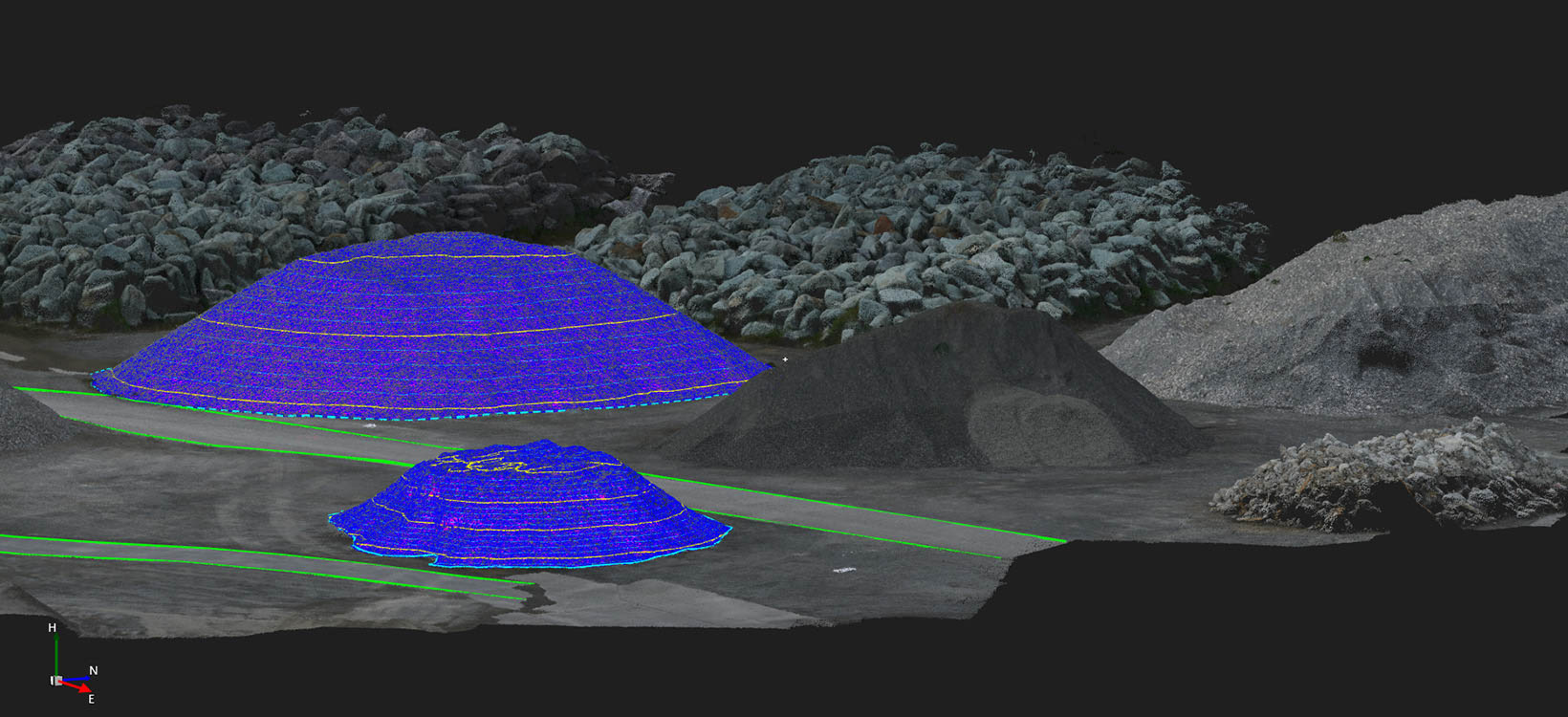

Stockpile management

Estimating stockpiles has always been a challenging task. Estimating by guess or by climbing isn’t efficient or always safe. Knowing how much stock you have left, trusting that you have been invoiced correctly by your suppliers, and calculating the right time to reorder are important aspects for saving costs and project transparency.

Calculating volumes of stockpiles becomes an easy task when executed with a UAV compared to traditional surveying methods. With a UAV, it is fast, safe and easy to capture data from large or small areas from the air. This data is used to create a 3D model and make accurate volume calculations.

With a modern UAV solution, it is simple to make stockpile management an accurate process with automated missions; using the same flight plan and workflow repeatedly saves time and effort while ensuring the only change in the data collection is the amount of stock in the pile.

Progress reporting for transparency

Having fresh data on every stage of the project as a base for coordinating workforces, machines, suppliers and subcontractors gives an undisputable advantage. Before UAVs, this has been a costly and even dangerous process. In construction sites with strict schedules, one must be able to cost-efficiently compare the as-designed to the actual situation of the site progression.

Flying and capturing data regularly, according to a pre-defined flight plan, provides a transparent view of the site progression throughout the project lifecycle and allows to document and compare the as-built status with the as-planned while tracking resources. This can be done safely from the air without disturbing the construction.

Having a constant flow of data from all phases of the project adds more transparency to the whole construction progress. Progress reporting can serve several different types of needs, such as communication with all stakeholders and planning for next steps. Users can use this data even for marketing.

Better together

Big hype in the market has been putting a lot of focus into UAVs being a “silver bullet” and a solution to all data needs. This has raised several questions whether it can really replace other technologies. Combined with existing traditional data collection methods, UAV technology can form a perfect union for smart construction data capture.

Changes in the regulation, flying beyond visual line of sight (BVLOS), and artificial intelligence will bring new opportunities to users who already know the process. We are just at the starting point of being able to use the possibilities of combining different technologies together.

Reporter subscription

Contact Leica Geosystems

Want to learn more? We're here to answer your questions.

Want to learn more? We're here to answer your questions.