Surpassing customer needs with 3D laser scanning

Customer profile

Author: Yoshie Katagiri

U's Factory Co., Ltd. is a Japanese company established in 2013 as a Building Information Modelling (BIM) management company, focusing on BIM for building and construction. Since its establishment, the company has used point cloud data captured by laser scanners to generate 3D models. Having determined that laser scanning enabled a dramatic reduction in the total time required to prepare various drawings, the company purchased Leica Geosystems 3D laser scanners. U's Factory has built up the know-how to optimally combine devices depending on the on-site circumstances to capture point cloud data efficiently.

Providing ‘only-one service’ to match customer needs

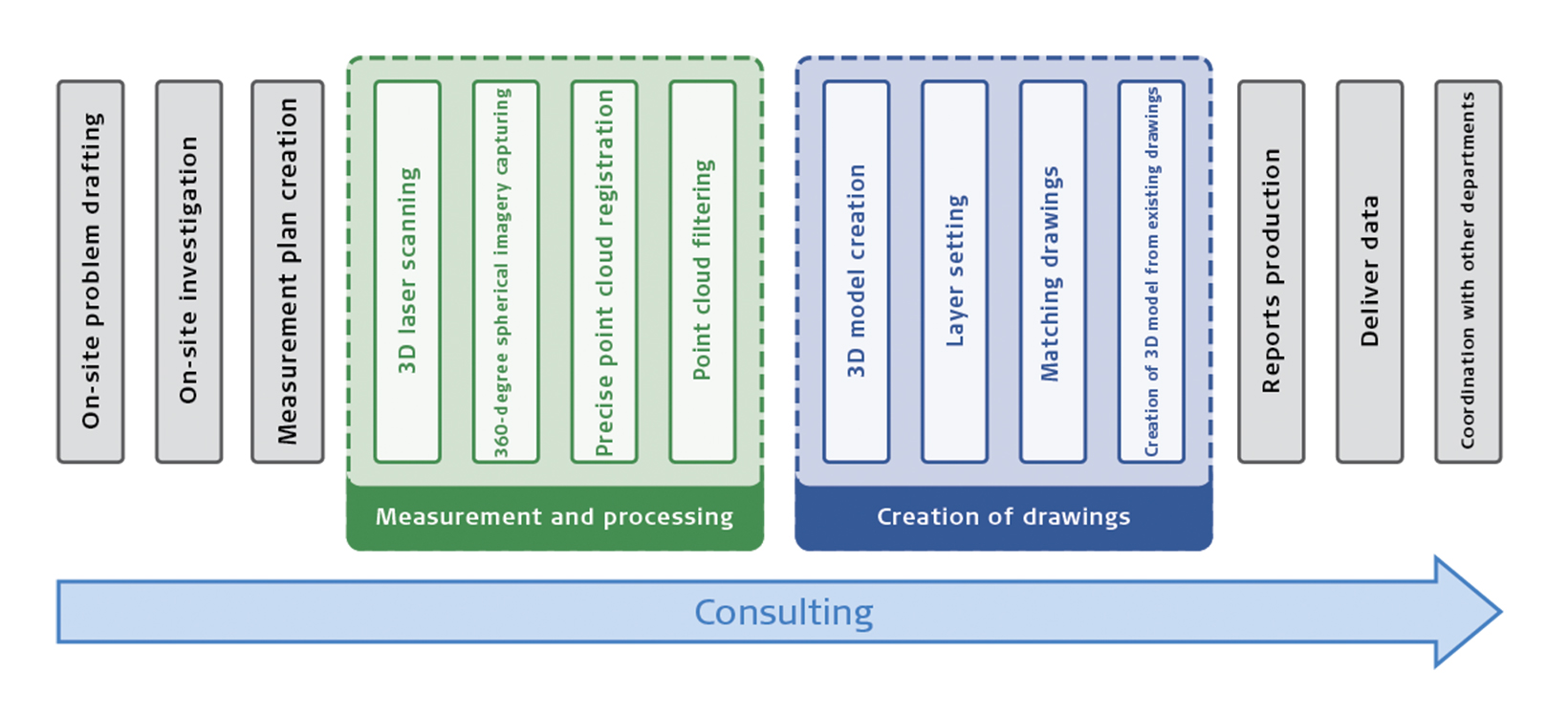

U’s Factory’s Only One Service

Surveying, 3D CAD modelling, and various design drawings are conventionally prepared and conducted by various separate companies on a process-by-process basis, which is labour intensive. U’s Factory CEO, Mr Yasushi Uejima, saw this as an issue while working as an engineer at a major general construction company. Based on his experience, he founded U’s Factory with the objective of using IT to dramatically reduce on-site work and revolutionise the industry.

U’s Factory provides one-stop services, including surveying and modelling for general construction companies and large design offices. The company offers not only 3D measuring and 3D modelling but also consultation services for customers to achieve their goal. This includes the delivery of optimised configuration, structural, construction and facility drawings – that is U’s factory’s ‘only-one service’.

Improving 3D laser scanning services with BLK360 and RTC360

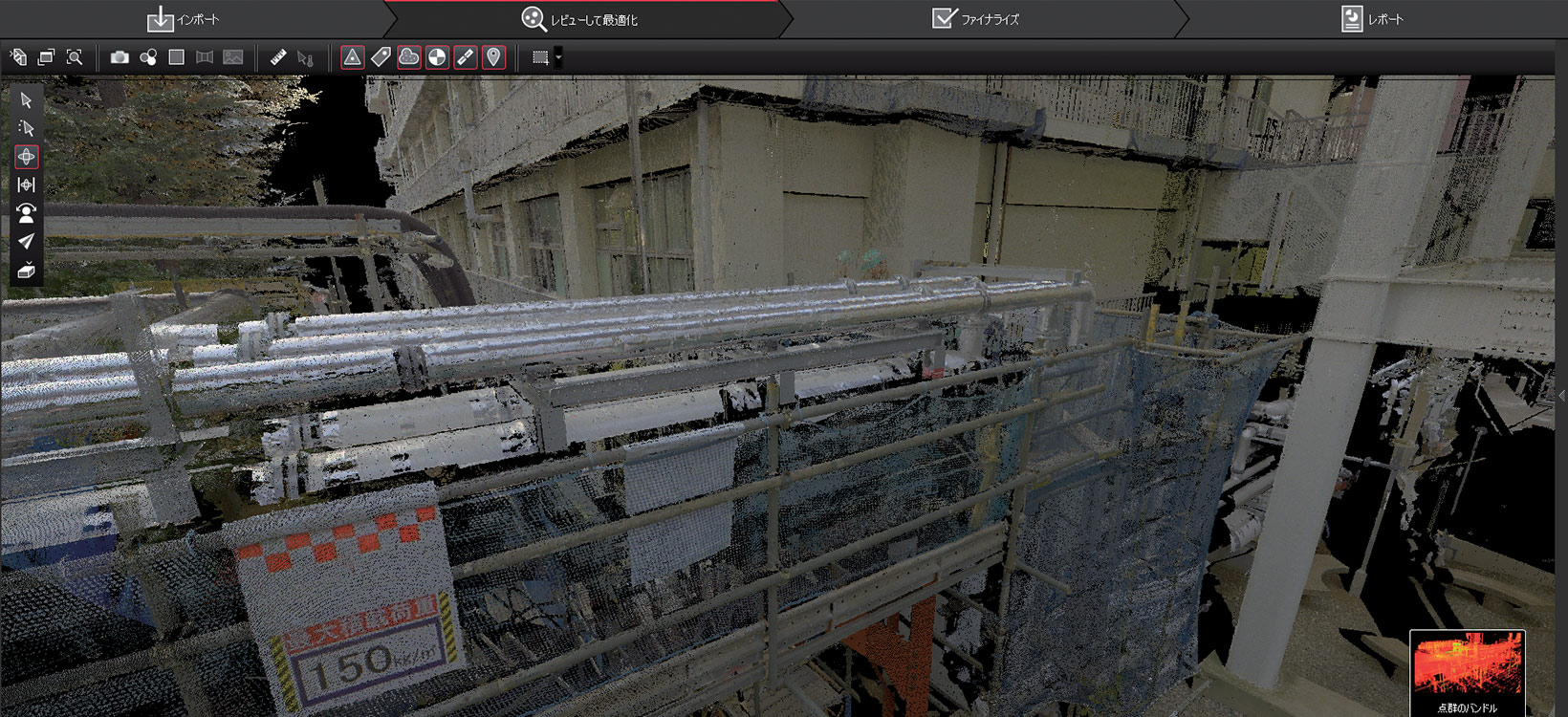

The use of point cloud data is firmly established as part of U's Factory's business model. As part of the company's pursuit to further improve its services, U's Factory purchased in 2018 the Leica BLK360 imaging laser scanner, Leica RTC360 3D laser scanner and Leica GS18 T GNSS RTK rover.

“The BLK360 is lightweight, compact, and scans fast. You can simply set up the device and just press a button. We’ve even used it in a project to capture as-built data of the piping arrangements in a confined machine room, which we couldn’t enter without crouching,” explained Uejima.

As for the RTC360, the company purchased the first unit available in Japan, receiving it immediately after its market release in September 2018. “The RTC360 requires even shorter time to scan than the BLK360, and it automatically recognises its horizontal level with the built-in tilt compensator. Another breakthrough is the way that the point cloud data can be transferred to a tablet so you can check the scanned area on the spot in real time. The situation where you go back to the office, upload the data to a PC and realise ‘Oh no, I should have taken more measurements here or there’ is much less likely to happen, so it’s highly efficient,” said Uejima.

These RTC360 features paid off dividends when Uejima surveyed an 8,000-square-metre holiday home site located in a woodland area with many large trees. “There were no other staff or equipment available, so I went by myself and completed the scanning in just two hours,” explained Uejima. In such environments, the scanning positions and arrangements are hard to be recognised in the captured data. However, since the RTC360 tracks its positions with integrated cameras, 27 scans without targets were efficiently completed and pre-registered on the spot.

Combining several devices to create an optimal survey plan

U’s Factory focuses its efforts on preparing the optimal survey plan to acquire the data that meets the objectives in the shortest possible time frame. The company delivers accurate measurements even quicker, having acquired several Leica Geosystems solutions, including:

- Leica Nova MS50 MultiStation

- Leica ScanStation C10

- BLK360 imaging laser scanner

- GS18 T

- RTC360 3D laser scanner

The shorter surveying time frame on sites pleases U’s Factory’s customers, especially when sites are still being occupied or have ongoing construction work. “By combining the RTC360 and BLK360, we were able to drastically reduce on-site survey work time. Of course, this does not mean that we can complete all the work with just the BLK360. Our starting point is to consider the client’s needs, and then, plan the optimal survey workflow with a combination of equipment with various specifications,” adds Uejima.

The company has built up knowledge and experience on how to make full use of all their equipment and perform on-site survey work in the most efficient way. U’s Factory experts, for example, survey geographical locations with the GS18 T rover, use the C10 scanner at an interval of 300 m with targets measured by the MS50 MultiStation, and use the RTC360 or BLK360 to fill the gaps in between.

The purposes for measurements have changed from acquiring just distances between two points to creating 3D models with appropriate drawing sets that can be even applied in augmented reality and simulations. The need for accurate point cloud data will surely increase as business opportunities expand and diversify.