The not-so-surprising secret to running a successful surveying firm

Customer profile

David E. Titcomb, PLS, runs a small but thriving survey business in Falmouth, Maine, USA. Founded in 1969 by David’s father, Robert P. Titcomb, PLS, Titcomb Associates has two offices, employs three professional land surveyors and six field crews, and has provided services to hundreds of clients in Maine, New Hampshire and Vermont, including numerous engineering firms and the Maine Department of Transportation (MaineDOT). Among the company’s key business decisions has been an unwavering commitment to providing excellent service and using best-in-class technology. It’s a forward-thinking strategy that often requires making significant investments — the sort that give many small business owners pause. But David Titcomb takes a different view.

“We’re always looking at how we can make life easier for our clients,” he says. “For example, we’re one of the few surveying firms in our region that works in MicroStation as well as AutoCAD, and MaineDOT and a lot of engineering firms prefer to work with us because they get files in the format that’s best for them.”

Achieving a faster turnaround on high quality deliverables is another way Titcomb Associates aims to provide better service. To that end, the firm recently invested in two new technologies after consulting with solution provider Maine Technical Source. One is the Leica GS18 T GNSS receiver, billed as the world’s fastest RTK rover, and the other is the Leica Nova MS60 MultiStation, which combines a laser scanner and a robotic total station in one platform. According to Titcomb, these investments have paid off in ways both predictable and unexpected.

GNSS that’s twice as fast… and safer, too

The GS18 T GNSS rover is one of the most technologically advanced receivers on the market. It’s both the fastest RTK rover and the first to provide the first true “plumb-free” pole solution—that is, the GS18 T uses GNSS and inertial sensors to make an antenna that always knows exactly where it is and, importantly, where the end of the pole is. It doesn’t need to be calibrated before use, doesn’t need to be plumbed before readings, and it’s foolproof against magnetic disturbances.

For Titcomb, these capabilities, combined with the “trust factor,” were far more important than price when considering the investment.

“Dad started with a Wild theodolite, so we’ve always had a trust in Wild and now Leica Geosystems instruments—they’re bulletproof. So I trusted this receiver to be as fast as advertised, and I knew that speed would pay off for us.”

Project Manager Nicholas S. Elliston, PLS, says that has definitely been the case.

“We’ve already seen the difference with the GS18 T being able to collect additional constellations and frequencies over our previous receiver. We’re now getting data in places we couldn’t have used RTK before—that’s a game changer.”

This is especially true given the particular conditions in Maine.

“We obviously have a lot of trees here, and we developed a good sense of where we could work with our previous RTK solution—more often than not, in tree cover, we couldn’t,” Elliston adds. “With the GS18 T, more often than not, we can. That means we don’t have to go back with a total station, and, of course, saving trips is a big-time saver.”

But it’s not just better coverage and faster readings that make a difference. According to Elliston, the calibration-free pole is a time saver in itself.

“Not having to take those couple of seconds to plumb a rod—for every single shot—speeds us up by 20-30 per cent. And it makes an even bigger difference when we can tilt the rod to get a shot right on the point we want—for example, building corners or the line under a guardrail. We get accurate locations without extra measurements or offsets or coming back with the total station. When all these factors are considered, there are projects we’re now doing in half the time compared to previous methods.”

A surprise benefit to the tilt rover was safety.

“We do a lot of roadway surveying on the Maine Turnpike,” Elliston explains. “I’m often working near live traffic, and now I can be a step farther away just by leaning the pole out and taking the shot without plumbing up. The increased speed is great, of course, but working more safely is probably the biggest advantage.”

Clearly, the investment in a more advanced GNSS receiver was a good one for Titcomb Associates, paying off with faster work, more effective work in Maine forests, reduced total station work, and greater safety. The firm leveraged the new receiver’s superb performance even more by making a further investment in an echosounder kit for bathymetric surveys.

“We connected the GS18 T to the echosounder and now we’re able to collect one shot every second when doing bathymetric surveys,” Titcomb says. “It’s pretty slick!”

What about the Nova MS60? It was a bigger bet on another advanced technology. Did it work out for this relatively small surveying firm in Maine?

The payoff of a scanning total station

When asked if he had any concerns before investing in a MultiStation that was nearly twice as expensive as a really good robotic total station, Titcomb is frank.

“Sure—it’s an expensive option for our relatively small company, and I had questions about our field crews being able to get the most out of it.”

So, what convinced him to take the plunge?

“My father was always convinced that a survey company needed to be able to gather a lot of information in the shortest time possible because, well, time is money. I agree with that, and I’ve also decided that we’ll only buy robotic total stations now because they give us so much flexibility and power,” Titcomb explains. “So, first of all, the MS60 is a great, and very fast, robotic total station. Adding scanning to that made sense for us. It lets us do work we couldn’t do before, is much faster for some projects, and, most importantly, I already knew that there was some work we were doing that would be much safer with a scanner.”

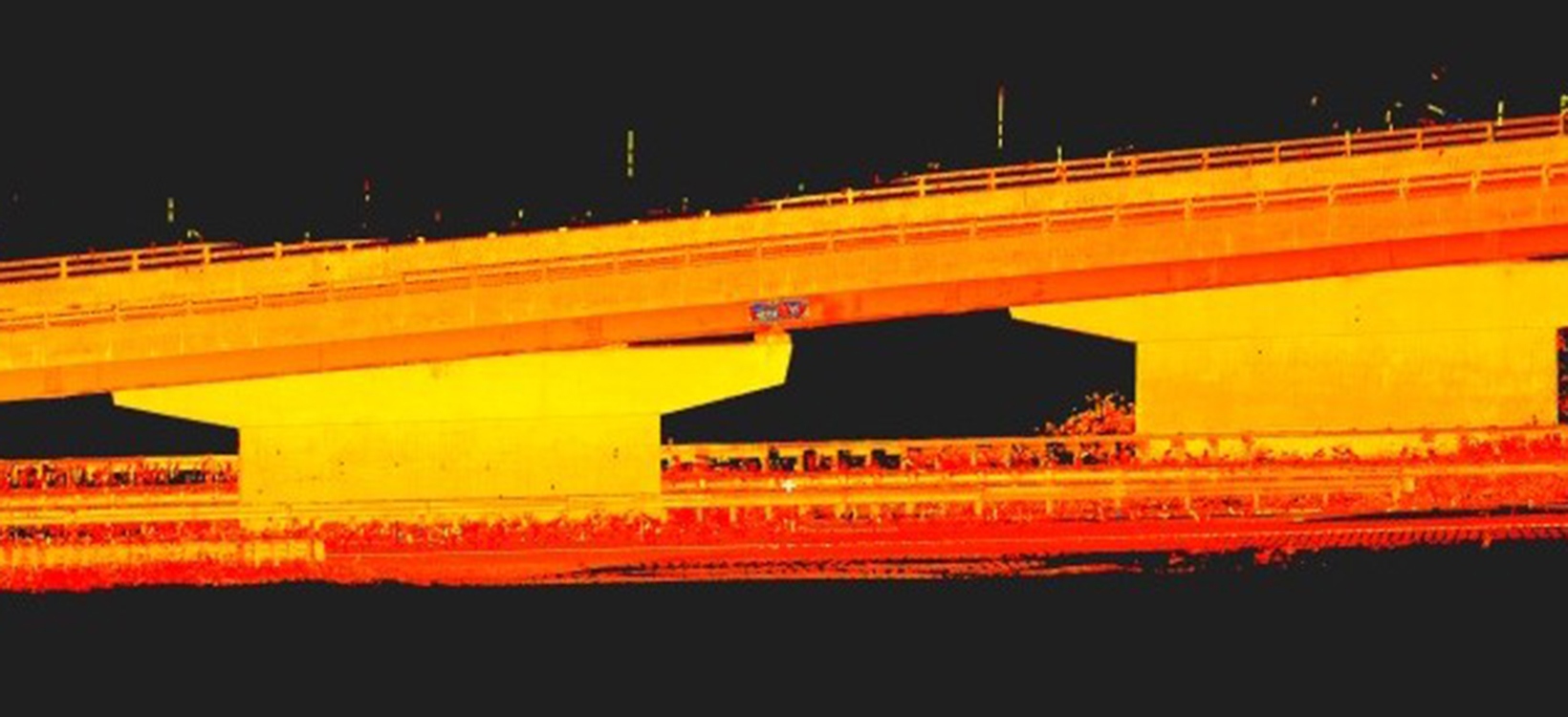

The work he was thinking of was roadway projects, one of Titcomb Associates’ largest areas of focus. The company regularly surveys bridges, roadways and intersections for a number of engineering consultants. “For interstate or turnpike projects, they’ll always close lanes for us, but there are some places, like on ramps, where it’s just really hard to do a lane closure and make it safe,”explains Titcomb. Now, in those situations, Titcomb crews set up the Nova MS60 well off the road and use the scanning capabilities to perform a fast, accurate topographic survey without getting anywhere near traffic.

The safety benefits of scanning are even more obvious when surveying bridges.

“We used to be up on ladders, near traffic, when we surveyed bridges,” Titcomb explains. “It was very unsafe. Now we’ll never have to do it that way again.”

Instead, his crews can simply scan the entire bridge deck in just a few minutes with greater accuracy than before and from a safe vantage point on the ground.

Aside from roadway and bridge projects, Titcomb Associates keeps the Nova MS60 busy with standard engineering and architectural support projects. The firm realised early on that most of their clients don’t really care how data is gathered, and very few in their region wanted a point cloud as deliverable. But the MS60, used as a scanner, can do most of this work—topos, as-built surveys, roadway cross sections, site monitoring, building interior surveys, etc.—much faster than conventional surveying, more accurately and more safely, while gathering far more data. An important side benefit is being able to view the point cloud data in the field with the Leica Captivate software to make sure the crew has captured everything they need before they come back to the office, thereby eliminating return trips.

“If we can do all that,” says Titcomb. “Then it doesn’t matter if the client knows that we’re using a scanner—we’re still getting a lot more quality work done and making money at it.”

A solid approach to business

Commitment to quality and to always working with the latest technology is not for the faint of heart, and it is not necessarily the right strategy for every survey firm. But for Titcomb Associates, it’s a strategy that has proven itself over nearly five decades and made the company one of the most trusted surveying specialists in New England, USA.

“It’s like my father used to say—'You have to spend money to make money,’” Titcomb says. “In our experience, that’s true. Spending money on advanced equipment from a reliable source has always worked out for us.”

The company regularly surveys bridges, roadways and intersections for a number of engineering consultants. Titcomb crews set up the Nova MS60 well off the road and use the scanning capabilities to perform a fast, accurate topographic survey without getting anywhere near traffic.

The safety benefits of scanning are obvious when surveying bridges and overpasses. Instead of climbing on ladders to obtain the data, crews can scan the entire bridge deck in just a few minutes with greater accuracy and from a safe vantage point on the ground.

Being able to view the point cloud data in the field with the Captivate software ensures the crew has captured everything they need before they come back to the office, thereby eliminating return trips.

Reporter subscription

Contact Leica Geosystems

Want to learn more? We're here to answer your questions.

Want to learn more? We're here to answer your questions.