City Street Survey Productivity Soars with the Leica AP20 AutoPole

Next-level surveying in Japan with the Leica AP20 AutoPole enabled faster projects and cut labour by 75% for significant cost savings.

BM Field, a surveying services company in Hokkaido, Japan, conducted efficient and accurate surveys for a residential road reconstruction project using innovative Leica Geosystems technology including the Leica AP20 AutoPole and Leica MS60 MultiStation. The combination of cutting-edge surveying technologies led to faster project completion using 75% less labour, increased measurement flexibility, and over €2,500 in projected cost savings - all while maintaining high accuracy and quality control.

The AP20 is an award-winning smart solution for robotic total stations that helps surveyors work more efficiently. It automatically compensates for a tilted pole and detects pole heights for faster measurements even in difficult conditions. With the AP20, surveyors can tilt the pole to reach points or avoid obstructions and maintain prism lock, removing tedious analog steps and enabling modern digital workflows.

Expert Surveyors Tackle Tricky Hokkaido Project

Located in Sapporo, Hokkaido, BM Field provides agricultural and urban surveying services throughout the northernmost island of Japan. The company’s work includes determining the quantity of farmland for local authorities, facilitating land improvement planning, and enabling disaster prevention through landslide monitoring and restoration plans. The BM Field team are well-accustomed to working in challenging conditions, including in irrigation canals and forests and on steep and rocky hillsides.

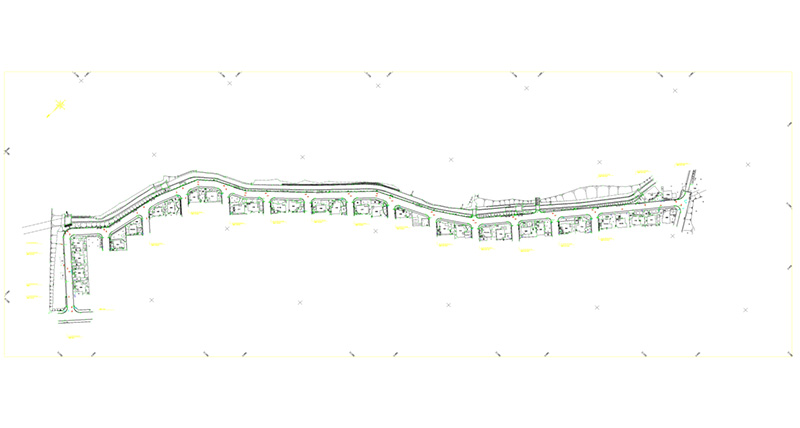

The team was recently contracted by Kitahiroshima City to survey a 700-metre residential road as part of a reconstruction project. The scope of work included surveying the road's existing conditions and 29 cross-sections to gather data for the redesign.

Since almost all of BM Field’s work is a one-man surveying operation using Leica Geosystems’ robotic total stations and GNSS, their greatest strengths lies in selecting the right equipment for the job. This enables them to work efficiently and flexibly, and provide reliable surveying results at fair prices.

With a tight 7-day timeframe due to active pedestrian and vehicle traffic, along with over 3,500 survey points including obstructed views from utility poles, fences, and other structures, the necessity of discerning the best tool for the job was even more pressing.

The project involved surveying many vertically aligned structures with highest accuracy to create a 1/500-scale plan of the existing conditions, including elevation of observation points, and a 1/100-scale cross-sectional plan.

AP20 AutoPole: The Optimal Solution

The demands of the project meant that traditional surveying methods would be difficult. For example, there were many places where the prism pole could not be set up vertically due to obstacles as well as offset observations. Therefore, the team selected the Leica AP20 AutoPole.

Tomokazu Aoyama, President and Surveying Engineer said, “We had already used Leica's GS18 T GNSS antenna with tilt compensation, and we were convinced that the AP20 would be very effective for this project, which required millimetre accuracy.”

Aoyama paired the AP20 with the Leica MS60 MultiStation, a highest-accuracy, laser scanning total station, and Leica Captivate field software. Leica Captivate offers a range of apps for survey work, including guidance to help surveyors easily and quickly find, record, and review points when working with the AP20.

The AP20's built-in tilt compensation and pole height detection technologies were critical time-savers for the crowded residential area. Tilt compensation and automatic pole height adjustments recorded in Captivate meant fewer MS60 setups were needed to maintain line of sight to the AP20. Working around obstacles easily and quickly and eliminating time-consuming manual height entries allowed one surveyor, instead of the usual four-person team, to complete the project in just three days.

Aoyama commented, “The time allocated to the work was less than expected, which allowed us to proceed with the work with a high degree of satisfaction, and we minimised the number of instrument setups required to collect all points by utilising the tilt function.”

AP20 Delivers Faster, Cheaper, Better Surveys

The BM Field team drew up a comparison between the actual cost of the project and the expected costs using traditional methods. They found that the Leica Geosystems combined solutions reduced the survey’s labour requirement by 75%, translating to approximately 400,000 JPY or €2,500 in total projected cost savings compared to conventional methods. Despite the accelerated schedule, accuracy remained high thanks to the AP20's precision and automated capabilities.

The AP20's faster surveying capabilities with a smaller crew delivered major efficiency gains and cost reductions for BM Field and Kitahiroshima City. With its multi-purpose benefits suited for varied environments, the AP20 streamlined the team's workflows for a quick return on investment.

Most importantly, the combined software and hardware from Leica Geosystems allowed BM Field to continue doing what it does best: fast, accurate and reliable work delivered at a consistently high quality for a fair price.